Inline process analysers in pharma and biotechnology

Automated maintenance relieves the burden on operators and simplifies procedures

It is a well known fact that production processes in the pharmaceutical and biotechnology industries are highly regularised. Operators follow strict procedures and checks are scheduled at every production step. The ultimate goal is to ensure the quality of the final product, minimise variations and eliminate "human errors". Automation plays a central role in this effort.

PAT

The FDA published the PAT (Process Analytical Technology) initiative in 2004 with the aim of better understanding, monitoring and ensuring product quality (QbD, Quality by Design). This starts with product identification, followed by inline monitoring of Critical Process Parameters (CPPs) and monitoring of process and product quality (KPIs) throughout the production chain.

Automation is indispensable in this respect. For PAT, this does not only involve performing the inline analysis, but also ensuring the quality and reliability of the measurement itself through calibration, diagnosis and continuous monitoring of the sensors. cCare is a concept that provides precisely this. For inline measurements such as pH or dissolved oxygen, you not only get a high-quality reading, the sensors are permanently monitored by continuously measuring and monitoring specific parameters that ensure correct operation.

Complete automation with cCare

The cCare system goes beyond this. Control and monitoring is one thing, but making sure everything runs optimally is another prospect all together. It automates labour-intensive maintenance and calibration (adjustment), thereby minimising human error. By only exposing sensors to the process when necessary, wear and tear is prevented and the service life is extended. cCare ensures that the sensor is stored, rinsed and cleaned under optimal conditions so that the next measurement will remain operational under the best possible conditions.

Applications for cCare

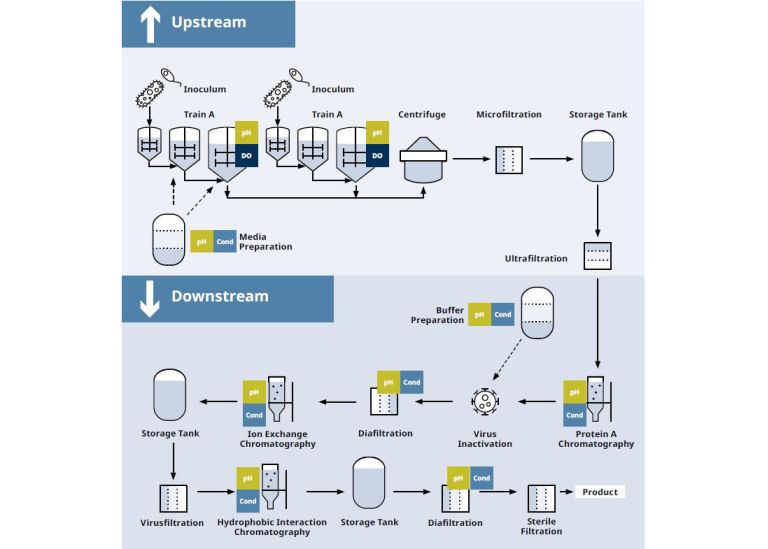

The cCare concept comes into its own in both upstream and downstream processes. Typical applications include media and buffer preparation, fermentation and control after filtration and chromatography.

The entire concept consists of a measuring converter with visualisation and digital communication (e.g. Profinet), a control unit, calibration and cleaning products and a pneumatically controlled sensor holder, which naturally includes a pH electrode or oxygen sensor. cCare is incidentally based on the 3x C principle: “Clean - Calibrate – Conservate”.

The sensors and pneumatically controlled sensor holders meet the specific requirements and needs of the pharmaceutical industry, with the appropriate certificates.

More information?