The first unbreakable and CIP-resistant inline pH electrode is here

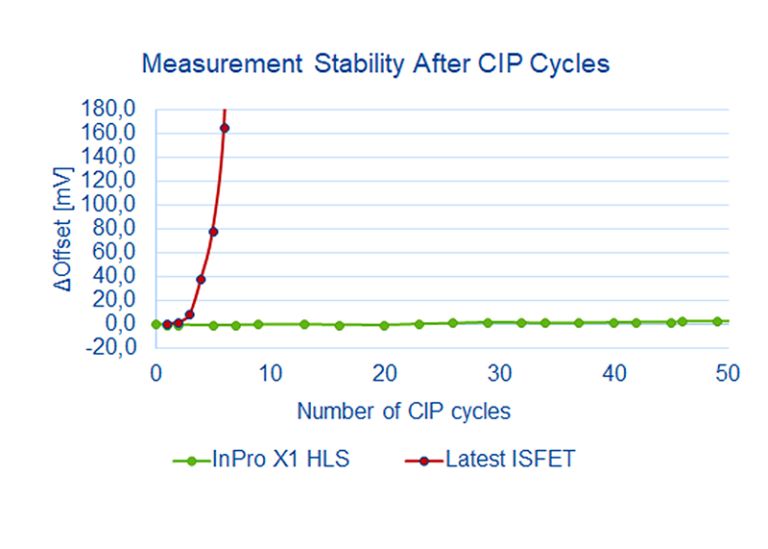

The general idea is to measure pH using a glass electrode. Glass is fragile, however, which is why we don't use it in processes in the food industry. Manufacturers are trying to find a solution with alternatives such as ISFET and enamel sensors, but so far without much success. An obstacle to a major breakthrough has been the limited resistance of ISFET sensors to cleaning, CIP (Cleaning In Place).

That is all about to change!

The X-chip

Mettler Toledo has developed the first-ever unbreakable, "food-safe" and CIP-resistant pH sensor for inline measurement.

The X-chip, the heart of the sensor, is made of high-tech composite material and it is virtually unbreakable. This reduces the risk of glass breakage in the process to zero. The InPro X1 HLS, which is the full name of the new electrode, is also capable of withstanding frequent CIP cycles. This is precisely the major downside of ISFET sensors, among others. The new sensor remains stable, even after dozens of cleanings. The product design and materials used comply with all relevant food directives such as EHEDG, 3A and EC1935/2004.

Rock solid

Stating that the InPro X1 HLS is unbreakable is not simply an empty claim: The sensor has withstood the "Drop test" according to U.S. military standard MIL-STD-810H with flying colours. The entire build is therefore rock solid with a food-grade PEEK shaft and Grade 2 titanium protection that simultaneously acts as a fluid grounding to eliminate electronic interference. The reference electrode is the renowned Argenthal cartridge, which is another Mettler Toledo development that has already more than proven its quality.

What is different?

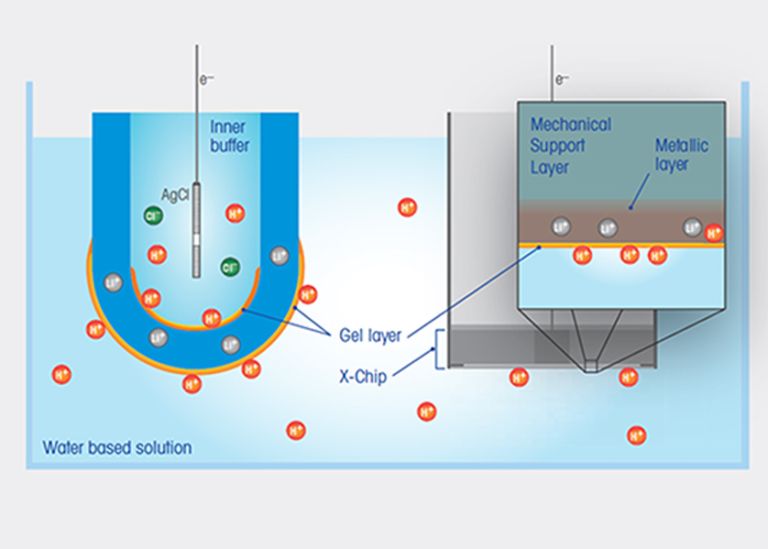

A classic glass electrode has a glass bulb that is filled with what is known as an "inner buffer". The potential difference between the inside and outside of the glass depends on the pH.

The new X-chip technology features no inner buffer, but several layers of solid material that guarantee a constant and stable potential. Besides that, the measurement technique is the same as before.

Inline pH measurement

The acidity (pH) of foods or ingredients is an important quality parameter, especially in the dairy industry. The end of fermentation in yoghurt production is an important moment, not only for the quality of the yoghurt itself, but also for the efficiency of the process. An inline pH measurement means you know the exact end point of fermentation and can move to the next process step faster. You gain time and quality!

A pH measurement is also done when checking incoming raw materials, for continuous quality control, as well as on the final product.

In short, safe inline pH measurement delivers higher efficiency by saving time and increasing the quality of the final product. Inline measurement is cheaper and faster than sampling and verification in the laboratory.

ISM, the digital support

Ultimately, InPro X1 HLS is an intelligent sensor, owing to its support by Mettler Toledo's ISM platform (Intelligent Sensor Management). The built-in intelligence provides an indication of lifespan, the sensor monitors itself and sounds an alarm when necessary. Digital communication makes it insensitive to electrostatic interference. An intelligent sensor also means a pre-calibrated sensor, so installation is truly "Plug-and-Measure". On-site calibration is no longer necessary.

Conclusion

The InPro X1 HLS is the sensor the food industry has been demanding for years. Unbreakable, CIP-resistant, reliable, low-maintenance, hygienic and with the appropriate certificates.

The sensor can be installed in any existing measuring position and is compatible with all Mettler Toledo measuring converters (and most others) that support ISM.

This all makes this revolutionary pH electrode a dreamed-of and immediately deployable alternative to ISFET sensors, which have a limited lifespan, or enamel sensors with pressurised electrolyte. It is suddenly also the perfect time to move away from sampling and manual checks.

More information?