Gas analysis, an overview

Analysers and detectors come in many types and sizes. However, not all devices are suitable for your application. Personalised, knowledgeable advice tailored to your needs is where we make a difference.

Safety first

In the process industry, oxygen meters are by far the most commonly used gas analysers. Safety is a key reason for using oxygen measurements, for instance, when it comes to explosion protection. In a potentially explosive gas mixture, there should be no, or only very little, oxygen present to prevent an explosion. Measuring speed is crucial for these applications. You should therefore ideally measure directly in the process pipe, as this is the only way to ensure a fast response time (<2 seconds). Compare this to traditional extractive analysers with sample lines of several meters long, where delays of 30 seconds to over a minute are common.

Smouldering fire

CO analysers are found in the same safety corner. CO, or carbon monoxide, can form, for example, due to self-ignition in storage silos that contain dry, dusty products. Typically in such a situation, the product starts to smoulder at a particular point. As oxygen levels are too low, incomplete combustion occurs and CO is therefore released. With continuous measurement or rapid detection, you can prevent a dangerous situation from escalating.

However, dust and gas analysers do not mix well. That is why we recommend a specialised filter, optionally with an automatic 'blowback' system, to keep the filter clean in dust-laden gas streams.

Quality in the process

We all strive for efficiency, optimisation, and minimal maintenance. Take chlorine gas, which is a basic raw material for many chemical processes. When moisture is present in the gas, chlorine becomes highly corrosive, which leads to wear, leaks, or worse. The right analyser can measure the moisture content down to just 1 ppm (parts per million).

Quality control is essential, but it also applies to the storage of both raw materials and final products. The headspace of large storage tanks can be monitored to ensure, for example, that there isn’t too much oxygen or moisture present. Such applications are referred to as blanketing. The tanks can also be flushed with nitrogen before filling them with product. This process is known as inerting. Both of these can be monitored without any difficulty.

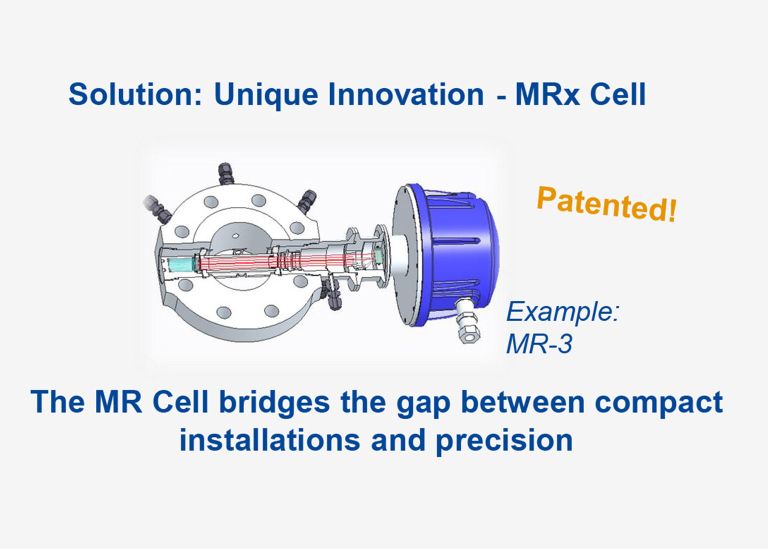

Smart solutions for small pipes

Process pipes do not always have a large diameter. Sizes of DN50 or DN100 are frequently used. However, for inline optical measurements, a long optical path length is important for measuring range or resolution. This might seem contradictory, but a gas analyser, integrated into a wafer cell with a special multi-reflection tool to extend the path length up to three times, provides the solution.

Our planet

We all recognise the need for more sustainable solutions. There is no magic bullet, and if every little bit helps, then biogas and biomethane certainly play a role. The production and upgrading of this energy source require specific analysers. This applies first and foremost for methane (CH4) and carbon dioxide (CO2), but also for hydrogen sulfide (H2S) and oxygen (O2). Maintenance and OPEX costs can be reduced using analysers and sensors specifically developed for these applications. At the same time, by continuously monitoring methane slip, you can also improve both quality and yield. Smart investments pay for themselves quickly.

More information?