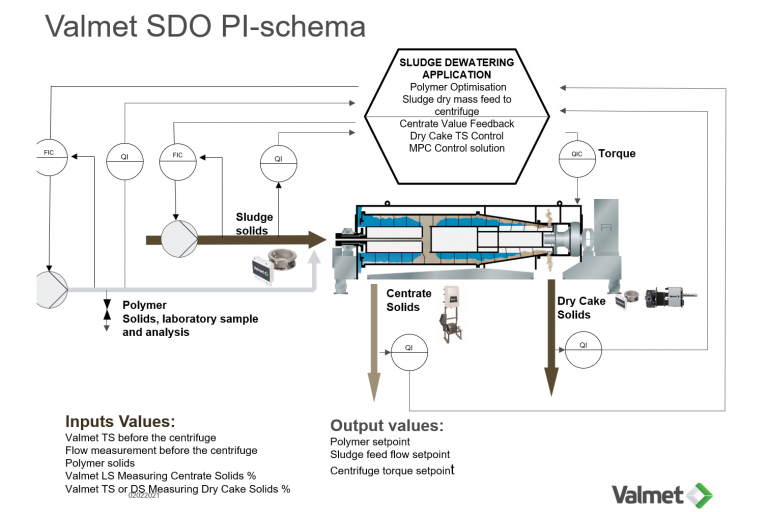

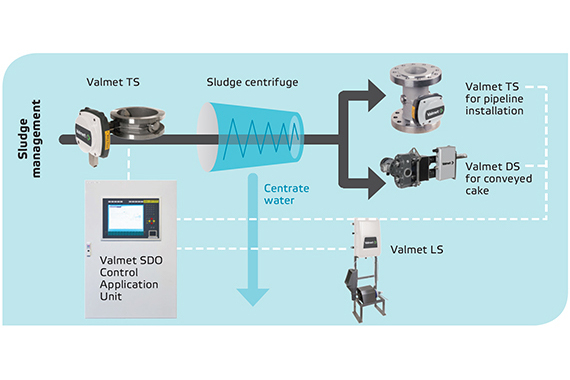

Valmet Sludge Dewatering Optimizer (SDO) for automatic control of wastewater treatment is the ultimate aim of every water treatment.

Valmet’s SDO automatically controls and optimizes the entire sludge dewatering line to obtain the maximum return from the installation.

The SDO is the investment for the future: partly due to the achievement of major savings in polymer and energy consumption, minimizing the amount of solids in the centrate water and maximizing the solids content in the dry cake. The result is a significant reduction in annual transport and combustion costs when dewatered sludge contains a higher percentage of dry matter. (A drier dry cake also requires less support fuel in the combustion plant.)

The SDO is self-learning, with which this technique strives for continuous optimization in:

- Polymer dosage.

- Torque of the centrifuge.

- Keeping total solids in centrate water below target.

- Supply pump for optimal supply to centrifuge or digester.

- Coherence of the above for optimal sludge dewatering.

- 24/7 optimization and performance improvement of the centrifuge.

- Continuous real-time insight into data.

- Automatic spin control.

- Higher dry cake solids.

- Savings on polymer consumption.

- Lower transport costs with drier cake.

- Polymer reduction through automatic control of PE dosing.

- Reduction of laboratory analysis.

- Lower fuel consumption during combustion.

- Efficient energy consumption.