The Valmet DS is focused on the continuous determination of moisture in dry matter flows in a wide range of industrial applications and wastewater treatment at WWTPs.

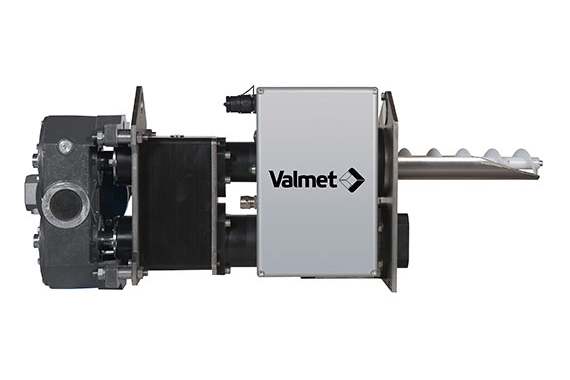

Samples are taken directly from the emerging dry cake stream by means of the sample screw. The microwave-based measurement technology makes it possible to determine the total solids content within a range of 15 to 35%. The total solids results are directly uploaded to your SCADA for real-time monitoring and controlling. An additional sample point for laboratory determination is integrated for optimal quality control and measurement adjustment.

The built-in calibration routine supports the operator in further optimizing the measurement, further increasing accuracy and reproducibility over time; Process controlling thus becomes the next level! The DS will obtain a prominent role in the further optimization of 24/7 automated control of the sludge dewatering process. This not only results in a higher efficiency of dewatered sludge, but also in cost reduction of energy, transport movements, polymer and maintenance of your systems.

Due to the robustness and auto-cleaning function of the measuring cell, the system has a severe low-maintenance interval.

- Accurate measurements on dry cake from 15 to 35% dry matter.

- Stable measurements result in a strong reduction of laboratory analysis.

- Well-regulated polymer dosing based on continuous dry matter determination not only results in savings on polymer costs, but also a more optimal sludge dewatering.

- Correct determination of dry matter makes your pumps, centrifuge and/or filter belt press function more efficiently with which a higher yield of dry matter can be achieved with less energy.

- Essential measurement for automatic process control and upscaling of production.

- Higher sludge efficiency contributes to lower transport and combustion costs.

- Reliable screw-based sampling.

- Built-in calibration routine.

- Remote industrial internet access.