Food & Beverages - Phase separation

Phase separation is one of the most common production steps in the food industry. Tanks and pipes are used for different products and are cleaned or rinsed between two batches. Usually with water, often combined with a CIP (Cleaning In Place), and sometimes one product is pushed away by another. In any case, it comes down to detecting the transition from one liquid to another as sharply as possible in order to avoid product loss.

Turbidity measurement

If one of the two products contains more particles than the other, and is therefore cloudier, a turbidity meter is the best choice. Think of the transition from milk to water, for example. With the right configuration, you can already detect very low turbidity values.

Photometry

With a photometer you measure the colour (intensity) of a product. When the products that follow each other have a different colour, you can determine the separation with a photometer at one or a few wavelengths.

Conductivity measurement

Measuring the conductivity of both liquids is certainly the simplest method of determining the transition between them. Especially when one of those products is deionised water or, for example, a cleaning product used during CIP.

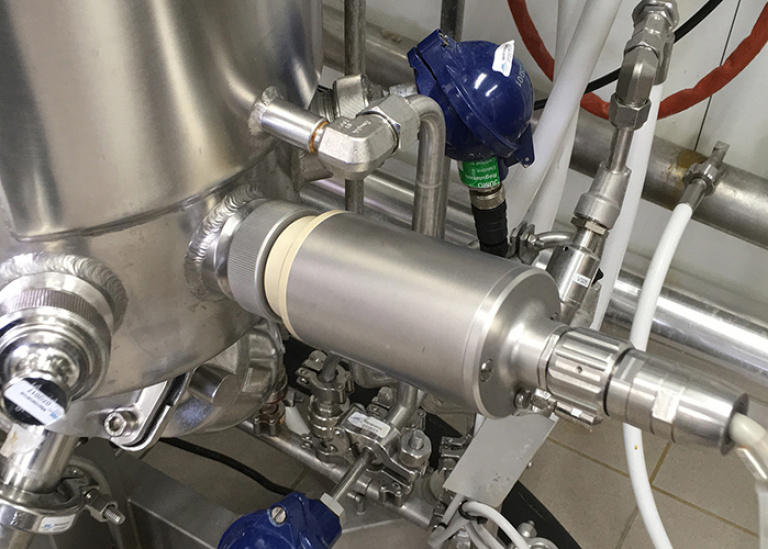

Refractometry

An inline refractometer or Brix meter is ideal for determining the mixing zone or boundary layer between two liquids. Especially when the products contain particles or fibres, or when you expect air bubbles or degassing. A refractometer is insensitive to this and also requires little or no maintenance.

More information?