Food & Beverages - CIP - Cleaning In Place

A CIP installation is used in very many food processes. Periodically, the entire pipeline system, including tanks, is cleaned with alkaline products and high-temperature water. Sometimes also with acid or other products. In the CIP installation, pure chemicals in high concentration are used, which are then diluted with water to the desired concentration or activity.

pH measurement

For good results of a CIP, the right pH is very important. pH measurement is therefore often used as a final check before the CIP products leave the plant. In view of the extreme values and high temperature, the correct sensor selection is necessary.

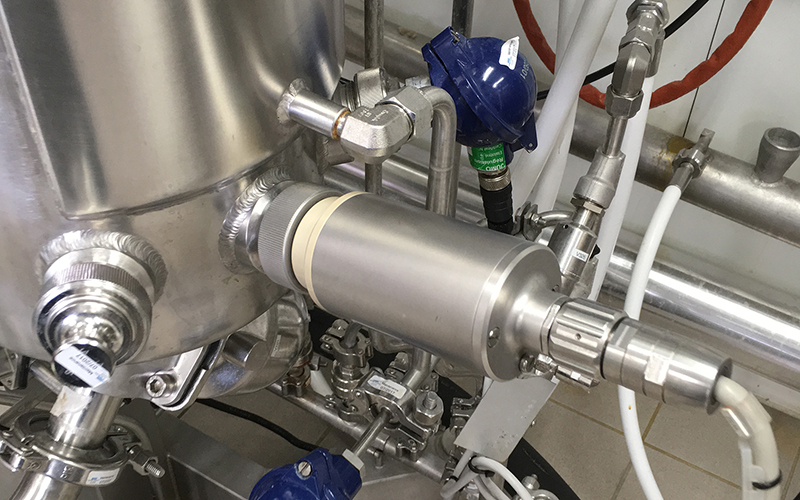

Conductivity measurement

Conductivity measurements can be used to determine the concentrations of so-called binary solutions. This technique is suitable for mixing/diluting the concentrated products. An inductive conductivity sensor is preferable because it is made entirely of plastic and thus cannot corrode.

Photometry

Depending on the concentration of the liquids, they absorb more or less light of specific wavelengths. You can measure this absorption with a photometer and thus determine the concentration of acid, base or disinfectant.

Refractometry

When it comes to measuring concentrations in liquids, refractometry (measuring the refractive index) is the most obvious choice. The sensor can be easily built into pipes and tanks.

More information?