Power - Make-up Water

The make-up water is the extremely pure pre-treated water used in the further steam cycle. The sources can include surface water, groundwater, recycled water and even treated wastewater. Depending on the type of water you use, purification is more complex and in-line quality control is more important. Various parameters must be monitored online to guarantee the ultimate water quality.

pH measurement

The acidity of pure water is a basic parameter for its quality. Due to the extremely low conductivity, a pH measurement is not clear. It is therefore important to choose an electrode with suitable specifications for this type of water. An intelligent and therefore digital sensor helps to increase the quality and reliability.

pH calculation

The pH value of pure water in the steam cycle can be calculated under certain conditions by combining two conductivity measurements: one before and one after the ion exchanger. Combined with a classical conductivity, this gives an increased certainty and one measurement monitors the other.

Conductivity

Measuring the (specific) conductivity is the simplest and most commonly used inline measurement for checking the quality of pure water. Intelligent sensors use digital signal transmission, which makes them much more accurate than their traditional analogue predecessors.

Degassed Cation Conductivity (DCC)

Acid conductivity is also called Degassed Cation Conductivity (DCC). Together with the degassed cation conductivity measurement and the ordinary or specific conductivity, they help to quickly detect the cause of contamination (saturation of resins, leaks, etc.).

Sodium, Silica and Phosphate Analysis

The monitoring and follow-up of water for steam production is all about avoiding corrosion and deposits. Sodium, Na+, is a major cause of corrosion. Silica (SiO2) is responsible for deposits and phosphate (PO43-) serves to prevent corrosion and hard deposits. This has a very negative impact on the efficiency and service life of the turbine in particular. It is important for analysers to have high autonomy, low maintenance and automatic calibration.

Chloride and sulphate analysis

When it comes to corrosion prevention, chlorides (Cl-) and sulphate (SO42-) are the most corrosive ions. Detection and monitoring from the lowest sub-ppb concentration level is indispensable in a power plant. For inline analysers, it is important that the analysis time is as short as possible (up to only 15 min.) and the periodic maintenance is limited (2-monthly).

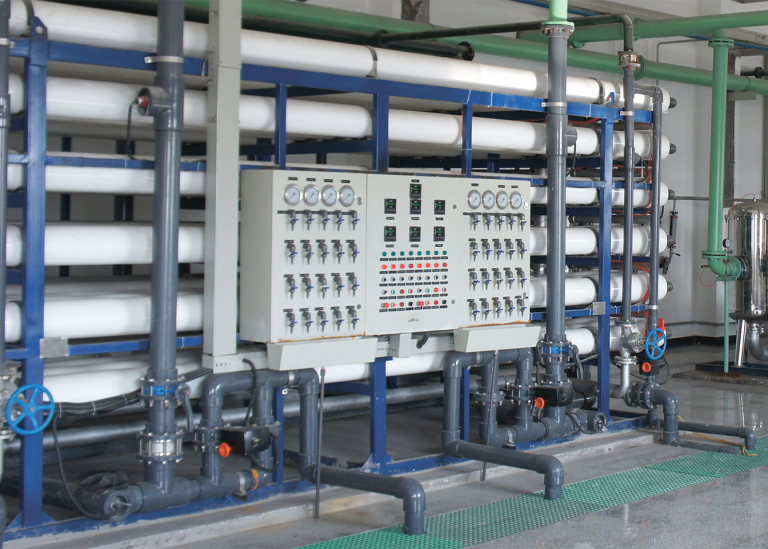

Steam and Water Analysis System - SWAS panel

"Steam and Water Analysis System", or "SWAS" for short, is a panel that brings together the most important process analysers. The simplest form is the combination of conductivity and/or cation conductivity with dissolved oxygen and usually also pH measurement. More comprehensive systems also contain analysers for e.g. Na, Silica, TOC, etc. The panels are often fitted with a so-called "sequencer". This is a system that switches between two or more partial flows which are then analysed in turn for a certain period of time.

TOC analysis

Total Organic Carbon is a very important quality parameter in the water and steam cycle. Unlike conductivity measurement, with TOC the organic and often non-conductive contamination is measured. And this is done on already low ppb level. Any kind of filter breakthrough or problem in a purification step will therefore be noticed immediately.

More information?