Food & Beverages - Fermentation

Those who think that biotechnology is a new science should think again. Fermentation is one of the oldest technologies we use. For centuries, food has been fermented to preserve it longer or to give it special properties such as taste and smell. Today, more food is fermented than ever. And it goes without saying that this must be done in a controlled way to ensure quality and food safety. The right measuring equipment will help you.

Fermentation processes can be found in various food sectors. From the production of beer, wine and other alcoholic beverages, through yoghurt and cheese to sauerkraut and sourdough.

pH measurement

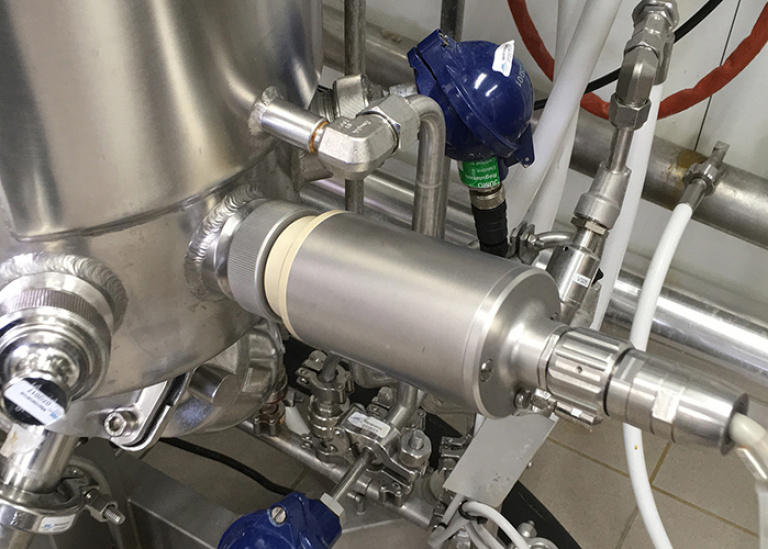

Each fermentation proceeds optimally at a specific acidity level. Using a pH measurement, we can closely follow the course of the fermentation, make adjustments or determine the end point. Choosing the right electrode for your process is the basis of good process monitoring.

Oxygen measurement

No fermentation without oxygen measurement! The amount of dissolved oxygen is one of the key parameters for a good course and result. Optical oxygen sensors are the most suitable. They require little maintenance, are easy to calibrate and are always immediately ready for use, in contrast to classical polarographic sensors.

Turbidity

In some fermentation processes, turbidity or optical density is a parameter that determines the course or end point. A turbidity meter that you can mount directly in the fermenter gives you fast and accurate results.

Brix measurement or Refractometry

Do you want to monitor the concentration of the solution you are fermenting? Then a refractometer is a good choice. It tracks the conversion of sugars and fats into acids and alcohols or other substances. The course of the refractive index is, as it were, the fingerprint of the fermentation process.

More information?