Gas analysis in small process pipes

Achieve high resolution with Tunable Diode Laser (TDL) analysers in DN50.

When it comes to Tunable Diode Laser analyser (TDL), we usually think of those robust enclosures mounted on either side of a large chimney, with a diameter of several metres. On one side is a laser source, and on the other is a detector. This image used to be accurate, until Mettler Toledo entered the market just over a decade ago with their "Probe Type" analysers.

Small but fine

The process industry is not limited to chimneys and large one- or two-metre pipelines. Typical process pipes have a diameter of 50 to about 300 mm (DN50 - DN100). This is not feasible with a classical TDL analyser, but it certainly is with the revamped concept. "Probe Type" analysers are made so that the laser and detector are housed in one unit, so that you only need one flange connection. The laser beam passes through the probe and is reflected back to the detector through a special reflector (the so-called corner cube). The laser beam therefore passes twice through the probe, which makes the optical path length (OPL) twice the physical length of the probe.

Practical example

The oxygen concentration in the gas stream needs to be measured in a process in the metal industry. Since there is a risk of explosion, the oxygen concentration should be as low as possible (< 1%), typically even close to 0%. Since this is a safety measurement, the response time of the analyser is very important, and it certainly should be less than 5s. The pipe has a diameter of DN80. The temperature can reach 120°C at a pressure of 4 bar (absolute).

While this may not be extreme, it still is a challenge. An analyser with a wafer cell (a circular flow-through cell) with a cross section of DN80 is the solution here. In the given process conditions, this setup enables the measurement of oxygen concentration with a resolution of better than 0.2% and with a response time of less than 2s.

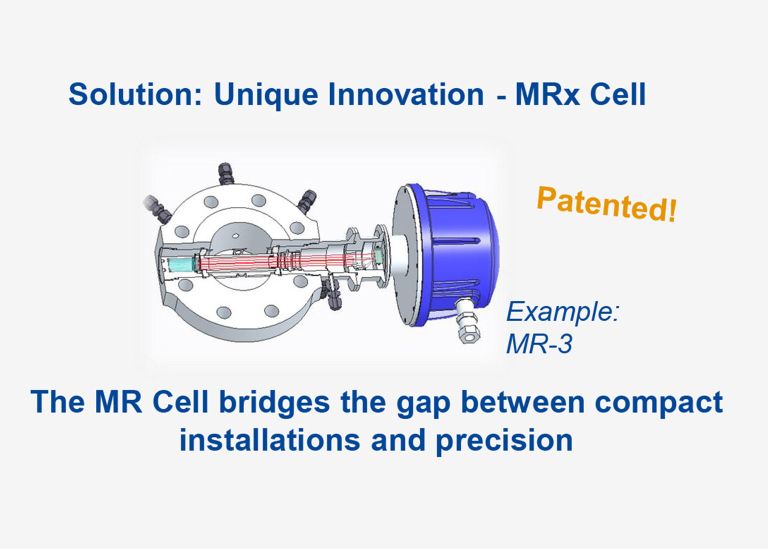

Smaller pipe, yet larger OPL

Mettler Toledo devised a unique concept for applications in smaller pipes such as DN50 where higher resolution (> 0.1%) is required with the so-called MR2 or MR3 (MR stands for MultiReflector), which increases the OPL by a factor of two to three times. Keep in mind that the laser beam is reflected, which doubles the OPL. The MR2 increases the OPL by four times the pipe diameter. With MR3, this is as much as six times.

This makes Mettler Toledo the "Technology Leader" for TDL analysers with the GPro500.

More information?