Gas analysers for process safety and cost reduction

If you ask process engineers and production managers what they expect from a modern gas analyser, the answers include: faster response time, higher accuracy, lower operating cost, less maintenance, improved process control, increased process safety and measurement reliability.

These answers boil down to increased process safety and cost savings. If that's not a coincidence: ELSCOLAB has the latest generation of Tunable Diode Laser (TDL) analysers that perfectly meet these requirements!

In-situ Probe Analysers

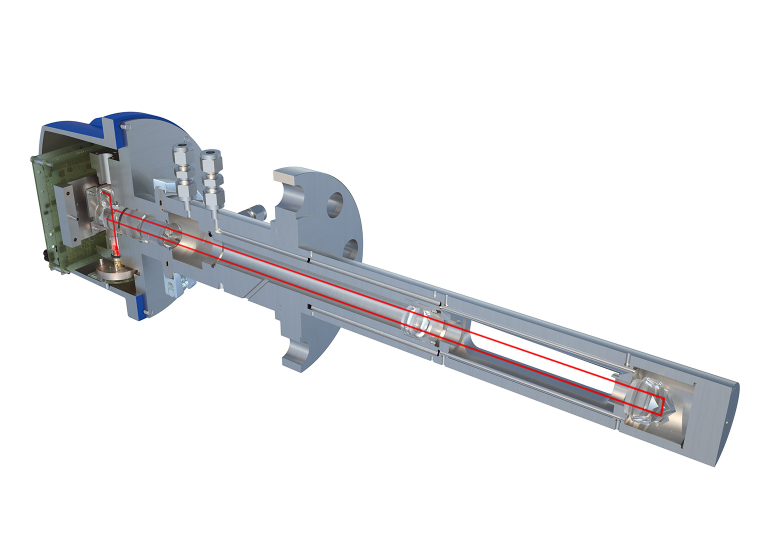

Laser analysers, or better TDL (Tunable Diode Laser) analysers, are known as the best analysis systems for most applications. The disadvantage of most TDL analysers is that the laser source and the detector are separate parts that have to be closely aligned to each other. This problem is solved by using a "probe" TDL analyser, an innovation from Mettler Toledo!

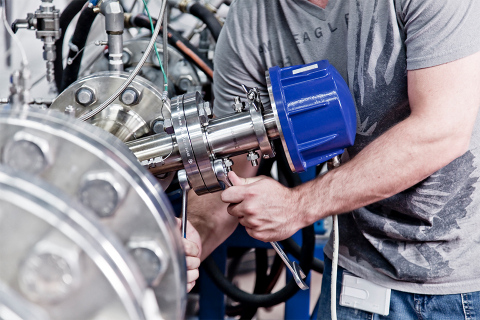

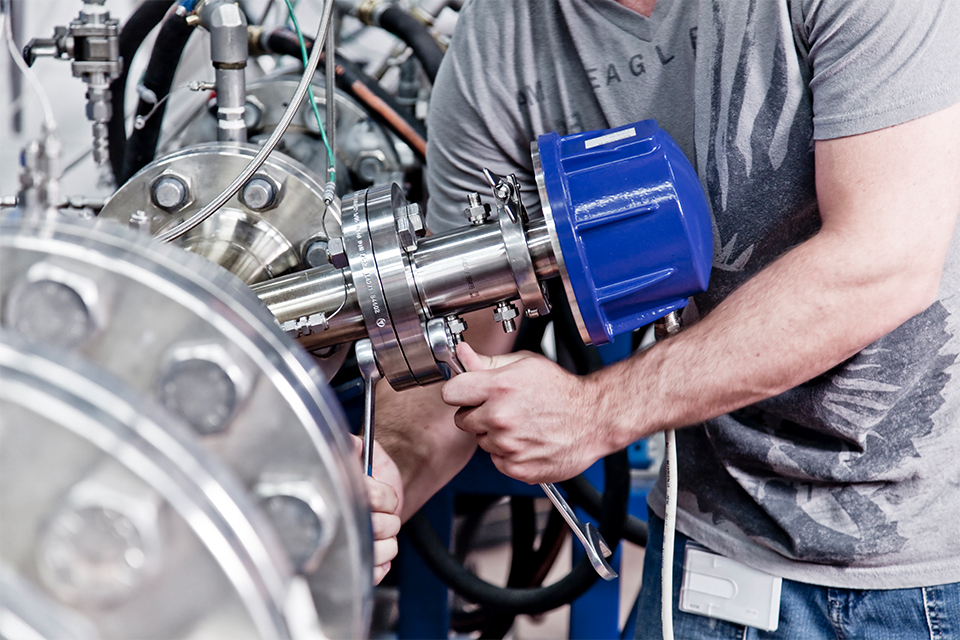

In these analysers, the laser and the detector are housed in the same housing. It follows directly from this that you only need one flange instead of two (for laser and detector) for installation in the process. This results in considerable savings. Not only because of the single flange, but because you do not need a double connection for power supply and purge air.

The key advantage of "probe" analysers is that you don’t have to align them! The classical cross stack analysers must be installed carefully and both the laser and the detector must be aligned properly. This is not always easy. Even more so due to vibrations in the installation and heating caused by the process. The procedure may need to be repeated after maintenance and calibration. And that is very time-consuming. Probe analysers are pre-aligned and form a single unit so that vibration and heating have no effect.

Can be used anywhere and suitable for all applications

Our analysers are modular. This means that you can adapt them to your requirements and process conditions. The probes are available in various lengths and materials, with or without filter, with or without purge gas and with or without blow-back cleaning of the filter.

Classic analysers have another limitation: the distance between laser and detector has to be large, about 3 to 4 metres or more. With a probe analyser, you can already measure very accurately from a DN50 pipe!

If an in-situ installation is not possible for any reason, you can very easily integrate a probe analyser in an analytical cabinet as an extractive analyser.

Process safety

Because you can install a probe analyser really anywhere, you can place it where it is really needed! By measuring at the critical points, you increase the safety of the process. You measure where it counts. The response time is only 2 seconds, in contrast to other analysis systems such as zirconium cells or paramagnetic analysers or electrochemical cells where you have to reckon on response times of 10 to 20 seconds. With extractive analysers, this becomes even more so if you have a long sample pipe.

Saving costs

A TDL analyser has no moving parts. In other words, there is no wear and tear and therefore no parts that need to be replaced regularly. So you don't have any costs either. Maintenance is minimal and (re)calibration or verification is normally done only once a year. Did you know that the start-up of a probe analyser takes only 15 to 20 minutes? The result of all this is that in the long term you have a lower TCO (Total Cost of Ownership) than with classic analysers.

Conclusion

A modern TDL probe analyser meets the most important requirements of process engineers and production managers. The flexibility of the installation and the low maintenance costs kill two birds with one stone: process safety and reduction of operating costs!

More information?