Inline refractometry for concentration measurement in liquids: the best choice

Quality, efficiency and safety

Regardless of which branch of the chemical industry you are in, the quality of a product and the process will always remain a top priority. That quality is determined, among other things, by the concentration or purity of a product. This is precisely why continuous inline concentration measurement is so important. Quality control ensures optimal processes, energy efficiency and safety at the same time.

Choose the right measurement technique

The choice of the correct measurement technique is therefore very important. When selecting the appropriate analytical equipment, it is essential to consider numerous factors, including process conditions, engineering, calibration, and maintenance costs. Naturally, you should also pay attention to the desired accuracy and repeatability. An important consideration in inline measurements is robustness. Stability is often more critical than accuracy. VAISALA inline refractometers take all conditions and requirements into account and are the most suitable for inline concentration measurement.

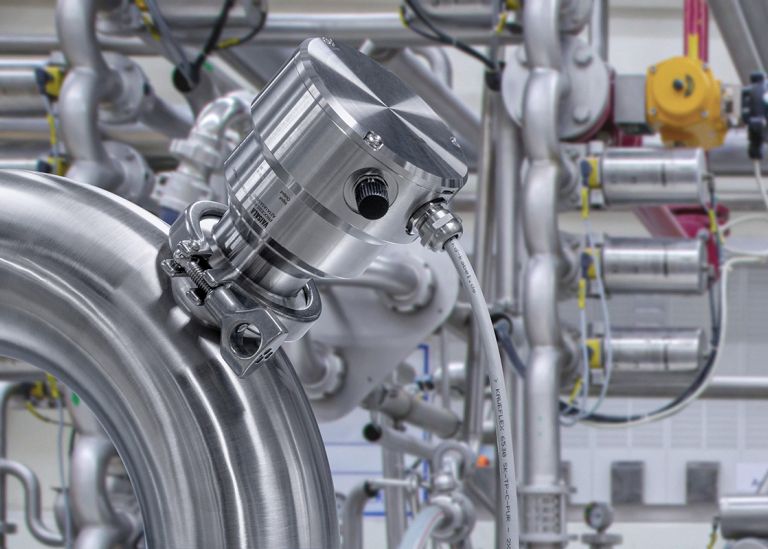

Install where it fits

No two measurement setups are the same. The best measurement point is directly within the process, in the reactor or the main pipeline. If this is not possible, a bypass or sample pipeline is a good alternative. An inline refractometer can be mounted at any desired location, e.g., in tanks and reactors, on large or small pipelines, whether straight, at right angles, or at an incline. Unlike density measurements, a process refractometer is insensitive to particles, air bubbles and vibrations. If there is a risk of contamination, various automatic cleaning systems are available.

Cost of Ownership

When selecting the most suitable technology, the cost of maintenance, parts, or recalibration is at least as important as the purchase price, which is often just a fraction of the total cost over the entire lifecycle. Refractometers are stable, with an annual verification being sufficient in most cases. Furthermore, there are no moving parts, which ensures extremely high measurement availability, ultimately leading to gains in process efficiency and product quality.

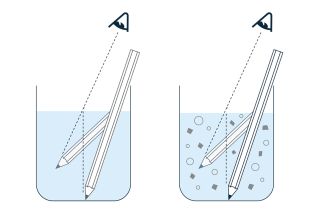

Refractometry versus density measurement

Refractometry is based on the refraction of light. Measurement of the refractive index is a highly accurate technique for determining dissolved substances in a liquid (the concentration). Density meters or densitometers measure the density of a liquid and then convert it into concentration. Various measurement techniques can be used for this purpose, e.g. Coriolis meters, ultrasonic measurement techniques, microwave measurement, and even nuclear techniques. All have their advantages and disadvantages such as particles and air bubbles in the flow, vibrations in the installation or deposits on the pipeline wall.