Viscosity measurements: Handling your equipment correctly

Viscosity measurements have long been crucial to ensure product quality, optimise processes and comply with international standards. The areas of application of this technique are extensive, ranging from the food industry and cosmetics to the strict standards of the pharmaceutical industry. Owing to the diversity of samples, it can be very challenging to make accurate viscosity measurements, however. In this blog, we explore common challenges in viscosity measurement and provide practical tips on how to achieve accurate and reliable results.

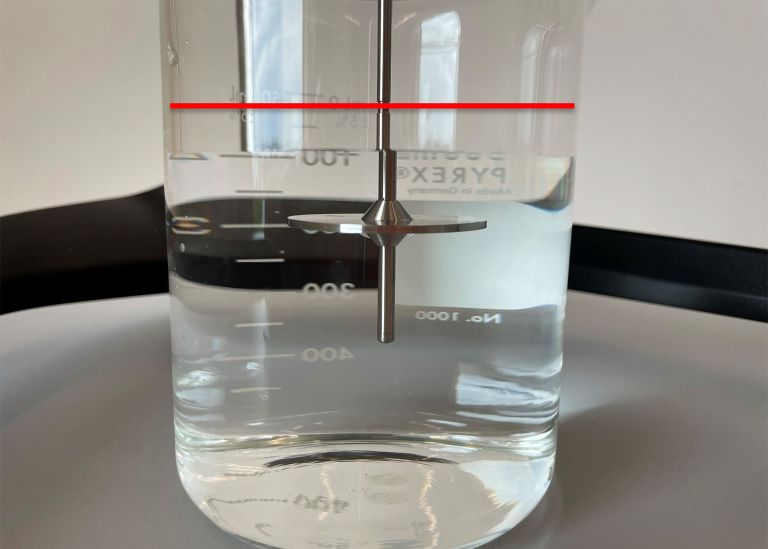

Sample volume

Always keep in mind that the spindle must be fully submerged up to the notch. Each spindle is accurately calibrated to measure to this level. Measurements higher or lower may cause biases in the results and consequently lower accuracy.

Eliminating external factors

Environmental factors, such as vibrations or large temperature fluctuations, can interfere with viscosity measurements.

Perform measurements in a controlled and stable environment to minimise the influence of external factors on the results.

Optimal use of Torque

When taking viscosity measurements, it is important to measure between 30-80% torque on your device. There are significant advantages to applying this range for accurate measurements.

Too low torque % could lead to measurements with too high a margin of error. This can result in inaccurate data and distort the actual viscosity of the sample.

Conversely, too high torque % could cause problems when a sample has a faulty composition or falls outside the expected viscosity range. The device will not be able to perform a measurement in this case, as it is unable to measure above 100% torque.

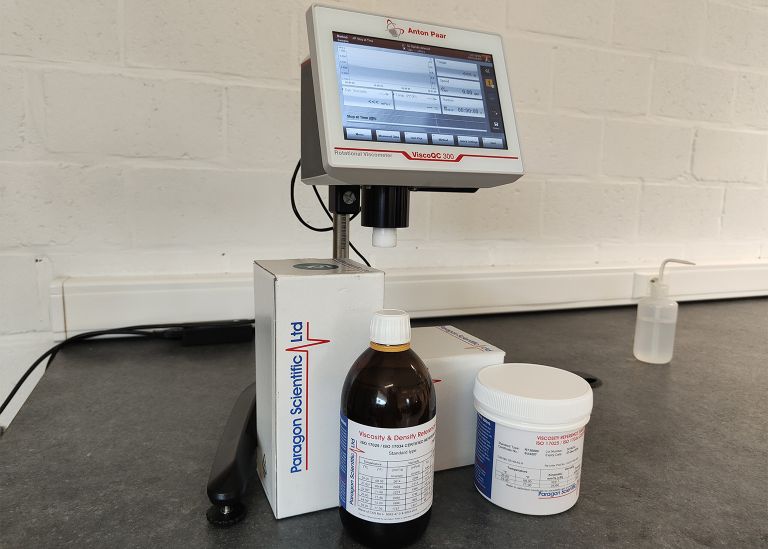

Calibration errors

Regular calibration and maintenance are essential to maintain the accuracy of your viscosimeter. Have your device checked annually and perform periodic calibration tests yourself using certified viscosity standards. This allows any anomalies to be quickly detected internally so that the device can be calibrated as necessary to provide reliable measurements.

Conclusion

Viscosity measurements are the cornerstone for ensuring product quality and fine-tuning industrial processes, but in all honesty, they can be challenging at times. Armed with these tips, you can confidently tackle viscosity measurements to take your industrial activity to the next level. Remember to regularly check your measurement practices and equipment to ensure consistency and accuracy in your results in the long run.

While we have shared a lot of useful information here, there is still so much more to learn about viscosity. We have years of experience at Elscolab and we have successfully completed a variety of projects. Besides that, we have also been giving seminars on viscosity for a long time already, both in our Kruibeke office and at external locations. So do not hesitate to contact us. We are ready to provide additional support and assist you with all your viscosity challenges.