Sludge Thickening & Digesters

The dewatering of sludge is becoming increasingly important. The costs of transporting and burning dry matter are rising. That's why it’s necessary to maximise its yield. The optimisation of the process ensures that these costs, including those for energy and polymer, are as low as possible. You can use real-time inline measurements for this.

Measurement principles

Optical measurement technology

The optical measuring principle is well known and widely used in today's industry. The turbidity, caused by the solid particles in the water, is measured by emitting light beams to a detector, which may or may not be scattered at a certain angle. Depending on how much light is detected, and therefore not absorbed by the solid particles, the turbidity of the water can be determined. And thus also the concentration of dry matter. This technology is often used in the measuring range of 0-6% TS.

Microwave measurement technology

This measurement technology uses microwaves that are sent through the water. This continuous measurement is placed inline and can be used in various pipe diameters. Microwaves travel more slowly in water, so there is a linear relationship between the concentration of dry matter in the water and the speed at which they are detected. They also suffer less from a varying water matrix in terms of dry matter concentration and require much less frequent calibration. They can also measure accurately in higher percentages of dry substances. This technology is used in the measuring range of 0-50% TS.

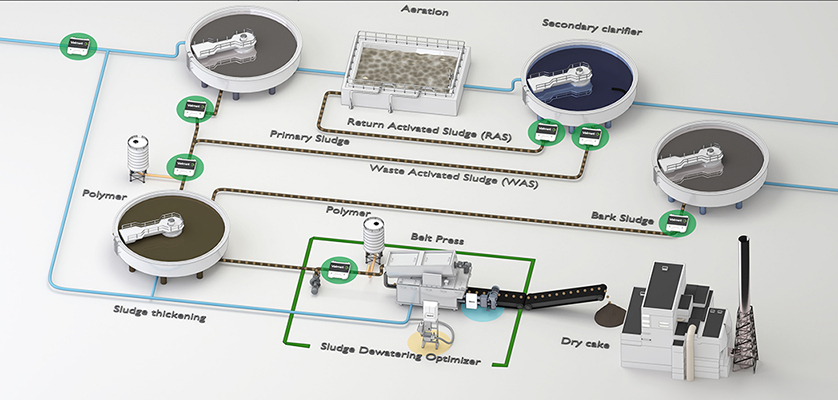

Placement locations for optimisation and advantages

The measuring equipment can be placed at various points in the dewatering process, each with its own strategic purpose and consequences.

Primary sludge

The purpose of monitoring the percentage of dry matter to the supply of the dewatering or transport is to increase the capacity, prevent the accumulation of solids and reduce the energy costs on sludge pumps.

Sludge thickener

The control of the percentage of dry matter sent to the sludge thickener results in a more stable and optimised thickening process that uses less polymer.

Digester

By optimising the sludge supply to the digester, an optimal fermentation process can be achieved with an accelerated fermentation time and optimal production of biogas. This increased capacity in the bioreactor results in lower heating costs.

Sludge dewatering

Using an integrated system, it is possible to automatically optimise the sludge dewatering process based on the percentage of dry matter measured in the influent, effluent and centrate water.

In this way, the functioning of the centrifuge, belt dryer or filter belt press is improved and an optimal yield of dry matter is realised. It also ensures a better polymer dosage and a reduced consumption thereof. The quality of the sludge and the centrate improves and results in the reduction of transport costs and energy consumption.

Dry cake - dewatered sludge

Better control of the dewatering process results in an increased percentage of dry cake. The fact that less water is present reduces transport and combustion costs.

More information?