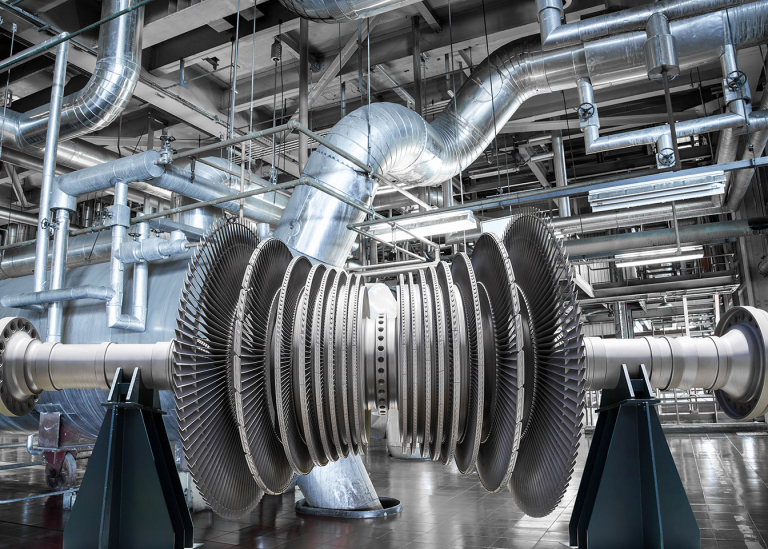

Power - Turbine

The turbine is the heart of the power plant. The steam makes the turbine rotate and therefore produces electricity. It is of the utmost importance that the steam is very pure. The slightest contamination has serious consequences on the service life and efficiency of the turbine. A conductivity measurement provides the quickest insight into the quality, but sodium and silica are also closely monitored.

Conductivity

Measuring the (specific) conductivity is the simplest and most commonly used inline measurement for checking the quality of pure water. Intelligent sensors use digital signal transmission, which makes them much more accurate than their traditional analogue predecessors.

Sodium, Silica and Phosphate Analysis

The monitoring and follow-up of water for steam production is all about avoiding corrosion and deposits. Sodium, Na+, is a major cause of corrosion. Silica (SiO2) is responsible for deposits and phosphate (PO43-) serves to prevent corrosion and hard deposits. This has a very negative impact on the efficiency and service life of the turbine in particular. It is important for analysers to have high autonomy, low maintenance and automatic calibration.

Steam and Water Analysis System - SWAS panel

"Steam and Water Analysis System", or "SWAS" for short, is a panel that brings together the most important process analysers. The simplest form is the combination of conductivity and/or cation conductivity with dissolved oxygen and usually also pH measurement. More comprehensive systems also contain analysers for e.g. Na, Silica, TOC, etc. The panels are often fitted with a so-called "sequencer". This is a system that switches between two or more partial flows which are then analysed in turn for a certain period of time.

More information?