Testimonial: Improved safety for operators and samples with a suitable LAF cabinet

PGI Nonwovens, leading manufacturer of non-woven materials

PGI Nonwovens, a subgroup of Berry Global, is a renowned producer of non-woven materials, including wet wipes and hygienic cloths used in the healthcare sector for surgical clothing, hygienic (cleaning) cloths, special fabric cloths for the automotive industry, etc.

Innovation is a core value at Berry Global that is deeply rooted in their corporate culture. They strive to develop innovative solutions to meet their customers' needs with a focus on continuous improvement and expertise in materials science.

What is it all about?

A new production line for the wet wipe industry has been operational at the Cuijk site since the end of 2022. It is of utmost importance to maintain sterility in this sector, which requires several checks to be carried out.

This includes checking for excessive growth of bioburden, yeasts and moulds. Samples are therefore taken and analysed with each production batch.

External or internal testing?

In the past, these tests were performed externally, but it was quickly decided to set up an in-house biological laboratory with clean-room conditions to perform the required analyses internally. The main advantage here is that the lead time becomes much smaller because they are no longer dependent on external parties for their own work schedules and staffing. It also removes transport times and possible loss of time if new samples have to be taken - due to an error.

They can test the samples themselves in their own laboratory, and in case of unclear results, they can retest with an additional sample from the same batch. Furthermore, this builds in-house expertise specifically focused on the non-woven industry.

Why work with a microbiological safety cabinet?

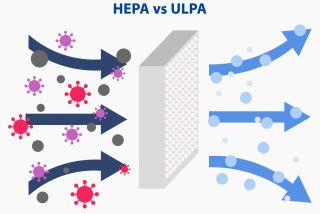

Following meticulous consultation, PGI Nonwovens opted for a Faster SafeFAST Premium class 2 microbiological safety cabinet. This cabinet allows them to work in a controlled and uncontaminated manner, preventing microorganisms from being introduced into the samples during testing. It is essential that laboratory technicians do not add anything to the samples, which is why good laminar flow is crucial. Moreover, the cabinet also provides protection for operators, which increases the overall safety of employees.

Samples are prepared in the cabinet with an advanced filtration system to remove bacteria, yeasts and moulds. The filters are then fixed on cassettes, which are then placed in the incubator.

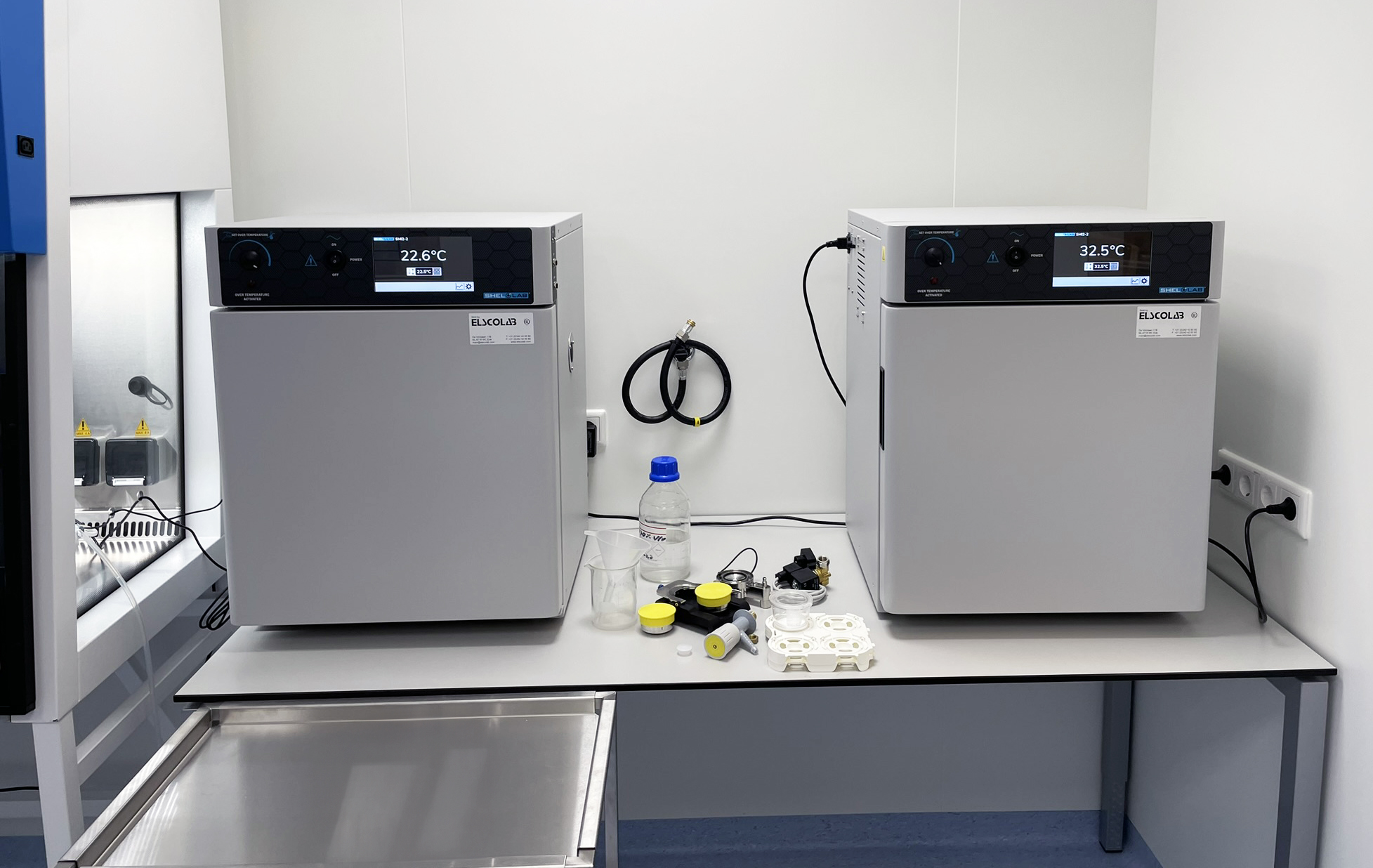

Guaranteed cultivation of cultures

It was decided to work with two separate incubators, each set with its own time and temperature, because different cultures require different environmental conditions. They have an incubator for yeasts and moulds, for instance, and an incubator for bacteria.

"What is especially convenient about the incubators is the registration and alarms. I am always aware of the status of the doors and I receive a notification if they are left open for too long, which safeguards the safety of the samples." - Erik Koeken, Quality Engineer at PGI Nonwovens

"ELSCOLAB's excellent advice and responsiveness to our needs have proved to be invaluable to our company."

- Erik Koeken, Quality Engineer at PGI Nonwovens

Why work with ELSCOLAB?

As PGI Nonwovens had a chemical-physical laboratory earlier, but not a biological laboratory yet, they were looking for a reliable partner who could support them in this.

During its search for a reliable partner for laboratory equipment, PGI Nonwovens came across ELSCOLAB. Their quick response and expert advice convinced them that they were the right partner. The fact that the two companies are also located in close proximity to each other is also convenient for further follow-up and service in the long term.

After a successful collaboration, PGI Nonwovens is certainly looking forward to working with ELSCOLAB again in the future, regardless of whether it involves expansions or innovations in their laboratory. They will also continue to rely on ELSCOLAB's service department for the maintenance of their equipment.