ChemPharma - Distillation

Distillation is a technique that aims to separate and purify mixtures of different products. Pressure and temperature control are important in the distillation process. The real control of the proper functioning is inline identification of the distillate and concentration measurement or determination of the purity of the product.

If you want to know what it is: product identification and purity determination

Refractometry

Inline refractometry, or refractive index measurement, is an ideal measurement technique for quickly and accurately identifying the product after distillation and determining its concentration or purity. After all, each product has its own specific refractive index.

Spectrophotometry

For more complex products, an online spectrophotometer is used. An absorption spectrum is recorded. Each molecule absorbs specific wavelengths. The computer analyses the spectra and tells you what product it is and in what degree of purity.

Photometry

When products can be identified on the basis of the absorption of one or two wavelengths, a photometer is recommended. It is simple to use and easy to maintain.

Ensure that everything can run smoothly using robust process monitoring

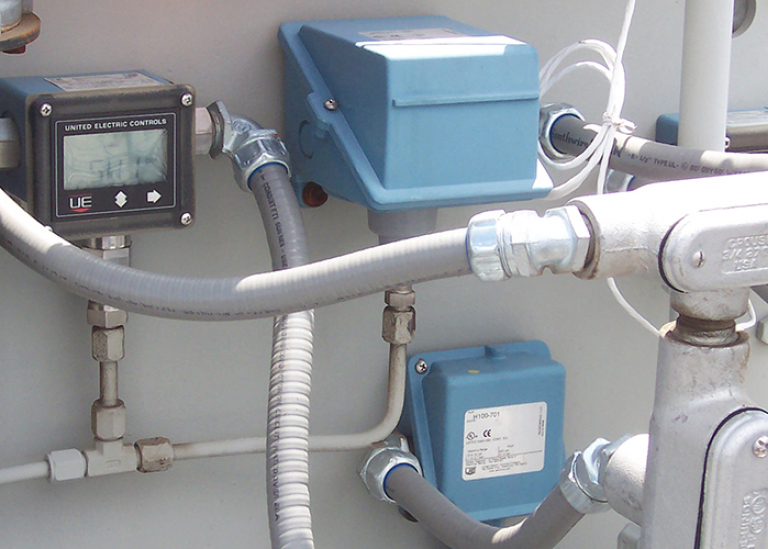

Pressure and Temperature

In a distillation process, temperature and pressure are decisive. Without correct measurement and control of these process parameters, there is no proper distillation.

pH and Conductivity

These basic measurements give a first indication of the proper process operation and help to prevent corrosion.

More information?