Viscosity measurements: Handling your sample correctly

Viscosity measurements have long been crucial to ensure product quality, optimise processes and comply with international standards. The areas of application of this technique are extensive, ranging from the food industry and cosmetics to the strict standards of the pharmaceutical industry. Owing to the diversity of samples, it can be very challenging to make accurate viscosity measurements, however. In this blog, we explore common challenges in viscosity measurement and provide practical tips on how to achieve accurate and reliable results.

Influence of temperature

One of the key factors that is often underestimated is the influence of temperature on measurements.

Even a small temperature difference can cause significant variations in viscosity. Make sure the temperature of the samples is homogeneous by giving them enough time to reach the required temperature. For example: a 1°C difference in water results in a 3% difference in viscosity. With more viscous samples, e.g. bitumen, this same temperature difference can give up to 15% difference in viscosity.

Use temperature control technology such as a PT100 sensor or Peltier heating element to keep the temperature constant.

Choose the correct spindle for the sample

It is crucial to select the correct spindle. If an unsuitable spindle is used, it could result in inaccurate measurements or even damage to the viscosimeter. A wide variety of spindle options is available, e.g. standard spindles, T-bar spindles, Vane spindles, and Cone&Plate spindles. Consult the user manual or contact us for guidance on how to select the correct spindle.

Container

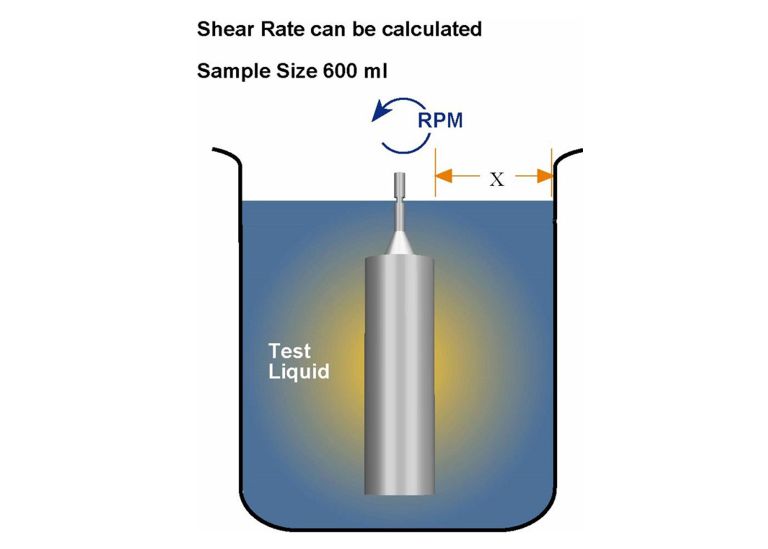

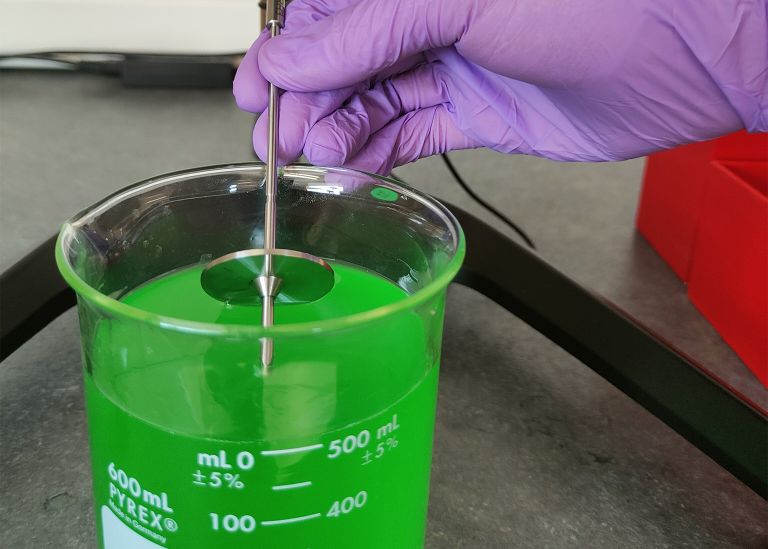

It is not only the sample itself that matters, but also the container in which the sample is measured. When measuring using standard spindles (RH1-7; L1-4) directly in the sample, the distance of the spindle to the wall (X in the photo) influences the measurement result.

Make sure there is enough space between the spindle and the wall and preferably use a bracket to keep this distance consistent. Also make sure there is enough space at the bottom of the container to prevent the spindle from making contact with the bottom.

Sample preparation

Improper sample preparation is a common cause of inaccurate viscosity measurements. Make sure the sample is homogeneous and free of air bubbles or contaminants that could affect the measurements. Insert the spindle at an angle into your container to minimise the amount of air bubbles. Special spindles, e.g. Vane spindles, are available for samples with particles.

Conclusion

Viscosity measurements are the cornerstone for ensuring product quality and fine-tuning industrial processes, but in all honesty, they can be challenging at times. Armed with these tips, you can confidently tackle viscosity measurements to take your industrial activity to the next level. Remember to regularly check your measurement practices and equipment to ensure consistency and accuracy in your results in the long run.

While we have shared a lot of useful information here, there is still so much more to learn about viscosity. We have years of experience at Elscolab and we have successfully completed a variety of projects. Besides that, we have also been giving seminars on viscosity for a long time already, both in our Kruibeke office and at external locations. So do not hesitate to contact us. We are ready to provide additional support and assist you with all your viscosity challenges.