Install & Forget

The reasons behind good quality

The reasons for its success are clear. Solid materials, high quality parts, good engineering and no moving parts are the foundation. Equally important is the fact that Vaisala K-Patents has from the very beginning specialised solely in inline refractometry, nothing else.

The result is a highly reliable analyser that measures Brix values correctly and with high accuracy for many years. It is so good, in fact, that you can easily forget that a measuring device has been installed.

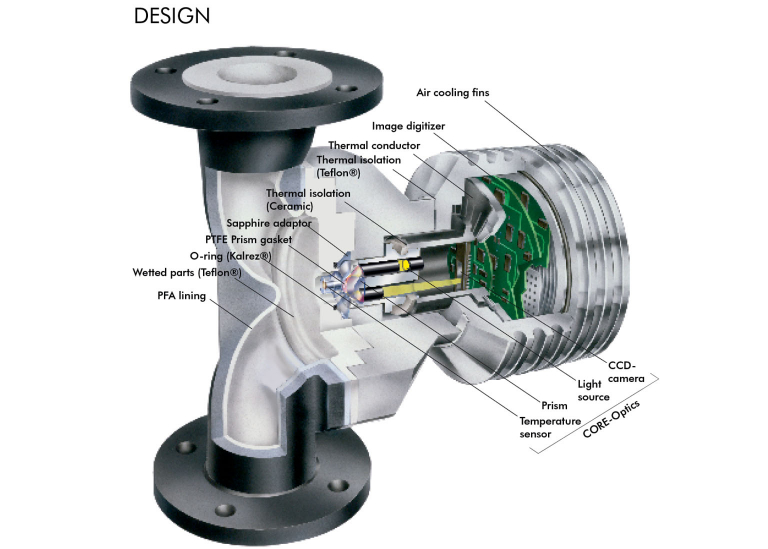

A look inside

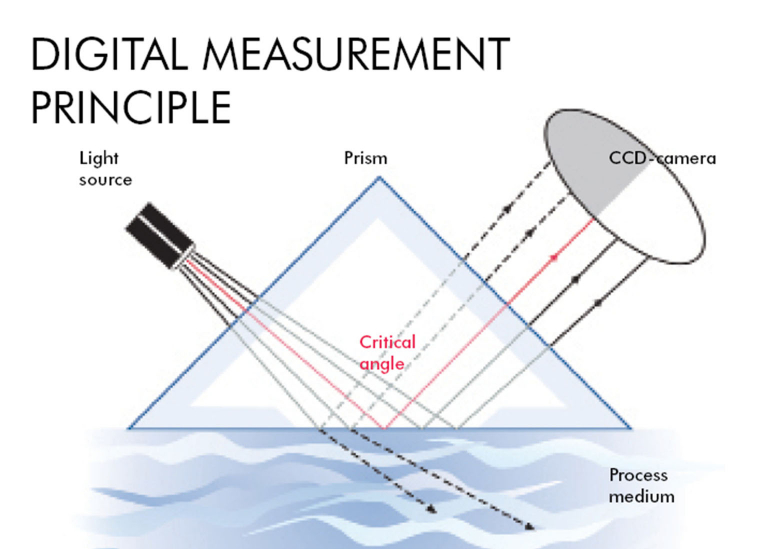

The Brix meters are surprisingly simple internally. The heart of any refractometer is the prism that causes the refraction of light. Needless to say, you also need a light source and a detector, which is a CCD camera in this case. All optical components (prism, light source, camera), as well as the temperature sensor, are combined in the CORE optics. A solid housing, insulated from external influences such as impacts and vibrations, ensures a remarkably stable signal. The whole is separated from the electronics by thermal insulation. The entire housing is also fitted with cooling fins that give the Vaisala K-Patents Brix meters their typical appearance.

Are alternatives available?

There are various technologies that can all be correlated in some way to Brix or sugar concentration. The most common measurement techniques are NIR, turbidity and density. The only thing they have in common with a refractometer is that they can all be installed inline, in the process line itself. Any other comparison stops there, however.

Refractometry is the only measurement technique that directly measures the concentration of the dissolved substance (Brix = sugar concentration). All other techniques measure a physical quantity that is influenced by the sugar concentration, but is only converted to it in a roundabout manner. For example, the speed of (sound) waves and other waves in the medium is measured and converted to density, which is only then linked to the Brix value. Add to this the fact that no drift occurs through the CORE optics, which means that the factory calibration is maintained. To summarise: there are indeed no real alternatives to an inline refractometer when it comes to Brix or concentration measurements.

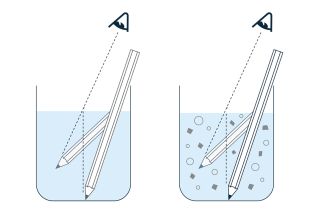

A refractometer has another advantage as is insensitive to gas bubbles or particles. The reason for this is that with refractometry you do not look at light intensity or wavelength, but at the so-called critical angle of refraction. This aspect also contributes to the long service life of the analyser, as the intensity of the light source does not play any role.

Why is an accurate Brix measurement so important?

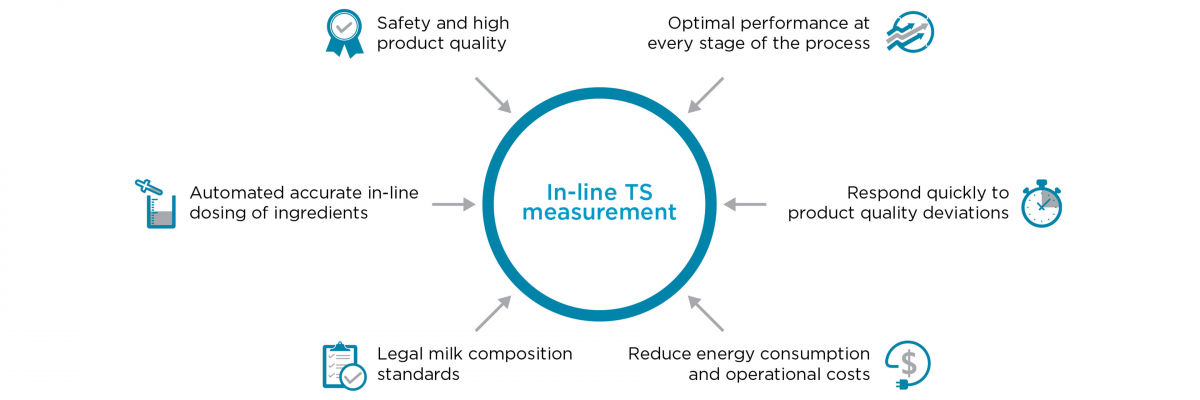

The food and beverage industry is one of the largest industrial sectors on a global scale. Production must comply with numerous national and international rules and guidelines and, most importantly, consumer expectations. All this must be checked and, above all, guaranteed. If not, this will have a tremendous impact on product quality and hold a major risk to food safety.

In addition to quality and safety, efficient production, sustainable use of raw materials and avoiding unscheduled shutdowns are important reasons for using adequate process analysers such as Brix meters. The days of sampling and lab analyses are long behind us.

Where exactly are Brix meters used?

The simple answer to the above question is "everywhere". Some of the most common application areas are listed below for the sake of clarity:

- Desserts

- Alcoholic beverages

- Dairy and baby food

- Sugar and sweeteners

- Fruit and vegetable processing

- Energy and sports drinks

- Fish and meat products

- Waters, coffee, tea, juices and soft drinks

- Egg products

- Oils and fats

- Additives and flavourings