Biogas analysers help to achieve major goals

Not so long ago, terms like climate change, carbon neutral or energy transition were vague concepts. Since then, perceptions have gradually started to mature, especially in the industry, among CEOs and entrepreneurs. Citizens are largely convinced that we should all try to avoid further global warming. Politicians have understood the signal and started setting ambitious targets. Europe, for example, intends to reduce CO2 emissions by 55% by 2030 and to be climate neutral by 2050. Biogas and biomethane play a key role in this.

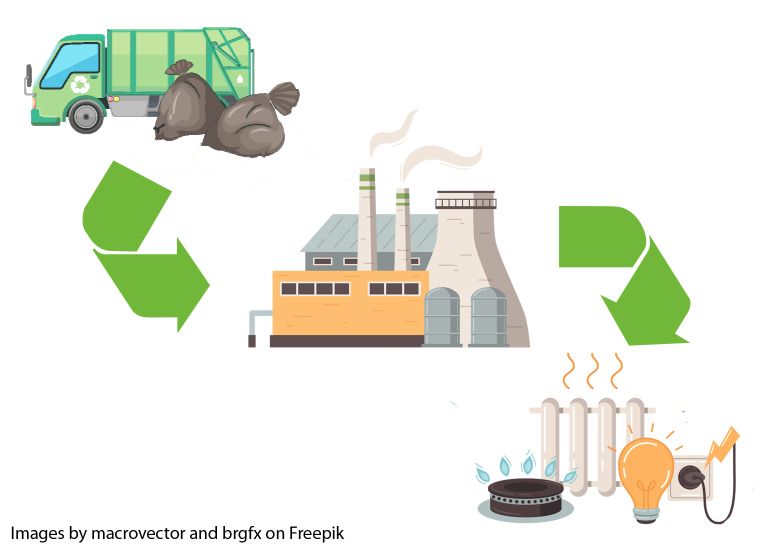

Waste to Energy, WtE

Today, we use waste as a source of energy. The production of biogas from the fermentation of organic waste is the best example of this. Biogas is converted into heat and electricity in a CHP installation. Biogas can already be produced on a small scale, such as bakeries or restaurants that meet their energy needs in full or in part in this way. Residential areas, sports centres or prisons are heated on a larger scale.

The next step is to purify biogas into biomethane. Biomethane is chemically identical to natural gas. It can therefore be injected directly into the existing natural gas grid to provide industrial production processes with the energy they need.

Multi Gas Probes can be used anywhere

An analyser is very useful in different places in the biogas and biomethanation process. This allows you to determine the CH4/CO2 ratio immediately after fermentation, which provides you with an insight into the bacterial ratio in the fermentation process and gives you the opportunity to intervene, if necessary. Further in the process, moisture measurement is especially important to monitor the efficiency of the heat exchanger and carbon filter. Protecting the CHP or gas engine against corrosion is by no means a luxury.

The membranes that provide separation between CH4 and CO2 when upgrading from biogas to biomethane are under high pressure, which increases the risk of condensation. Moisture measurement helps you increase membrane lifespan and efficiency. Finally, there is monitoring of the methane slip. You can route the methane-rich gas back to the installation entrance based on that inline measurement in order to separate again.

Capturing CO2

The best way not to emit greenhouse gases is not to produce them. That much is clear. If that is not possible - combustion processes will remain for some time to come - then you have to avoid releasing CO2 and CH4 (methane) into the atmosphere. This capturing of mainly CO2 is known by the term Carbon Capture. There are numerous techniques and processes which can isolate CO2 from a gas stream. Some methods actually yield very pure CO2 that is used in the food industry, for instance. Researchers are working hard in universities to find better and, above all, cheaper techniques.

The captured CO2 needs to be stored (CCS, Carbon Capture and Storage) for later use as a raw material (CCU, Carbon Capture and Utilisation) for the production of chemicals that are currently being produced in less sustainable ways.

Save costs while increasing your yield by simultaneously measuring CH4, CO2 and moisture (H2O).

How much? The tale is in the numbers!

Measuring devices are necessary in all processes, including biogas and biomethane production, as well as with CCU and CCS. Direct, inline measurement of methane (CH4) and CO2 provides invaluable information on the actual operation of the process. This allows for measurement results to be used immediately to control the process, while the information obtained is crucial for better understanding and optimisation of the process. All of this ensures better efficiency and lower costs.

Biogas contains high levels of moisture after the fermentation step. Relative humidity (RH) is (almost) 100% and water is a "killer" for motors, pumps and the CHP. Besides measuring the CH4 content in the biogas, it is therefore really necessary to determine the moisture content inline. If you want to purify biogas into biomethane, moisture should be completely eliminated. Naturally, it is necessary to continuously measure "methane slip", the residual flow of CH4 in the off-gas, so that you can monitor and adjust the purification process.

In CCU and CCS processes, it is important to continuously determine the efficiency. This can only be done with inline analysis of CH4 and CO2. Classical extractive analysers, such as GC or IR absorption, are not as suitable for this purpose due to their slow response time, frequent maintenance and the need to first remove moisture from the sample, among other things, which changes the composition of the gas stream.

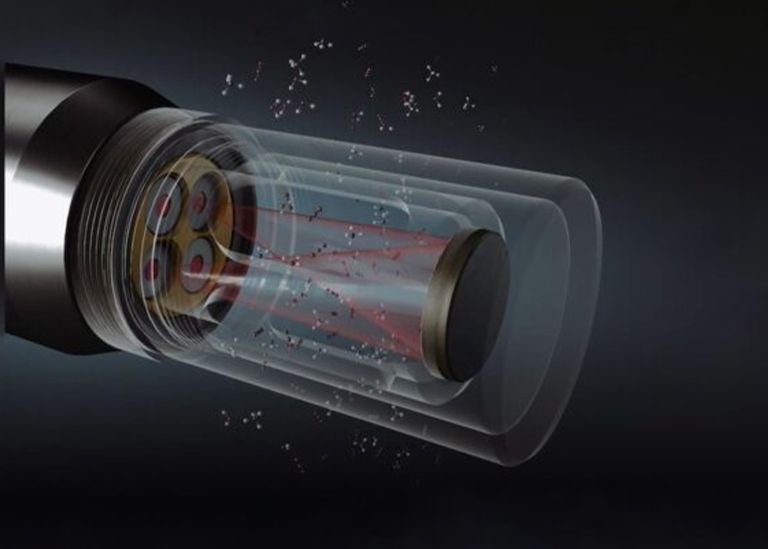

VAISALA Multi Gas Probes

Reliability, robustness and accuracy are very important in PAT (Process Analyser Technology). In an industrial environment, the time an analyser requires for maintenance is a decisive factor in choosing an analyser. Fortunately, Multi Gas Probes (MGP) are available from Vaisala. VAISALA has developed the first-ever inline analysers for biogas and biomethane. The MGP261 measures methane, CO2 and moisture simultaneously, inline and continuously, without pumps or other moving parts. This minimises the need for periodic maintenance. Calibration is only needed once a year. The MGP requires no carrier or purge gas and therefore operates completely autonomously.

More information?