From waste to bio energy

Waste is the new raw material. In particular if it’s of organic origin. Bio-waste can be converted into biogas, bio energy and heat. On top of that, it is an important form of renewable energy production.

What is biogas?

Biogas is obtained through anaerobic digestion. Bio-waste is broken down with the help of various micro-organisms to form biogas. Its composition may vary. It normally comprises of 60-65% methane (CH4) and 30-35% carbon dioxide (CO2). The raw biogas also contains water vapour and traces of other gases.

Biogas can be produced from various sources such as household and (non-hazardous) industrial waste, landfill sites and sludge from water treatment plants.

Biogas production

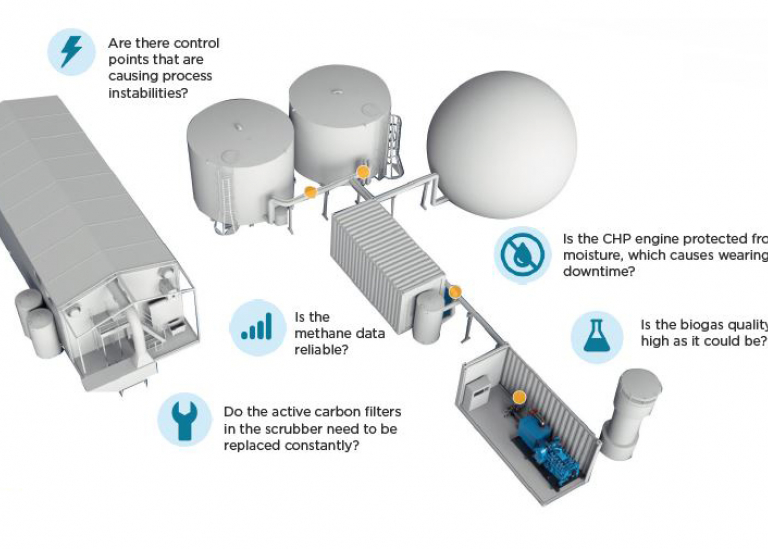

The production of biogas takes place in various processes. The waste is converted into biogas in the digester tanks. From there, the gas goes to the gas storage tank. The biogas is then further treated and purified by an activated carbon filter. The pure biogas goes to a Combined Heat and Power engine (CHP). Finally, the gas goes to a biomethane upgrade unit.

As with any process, the production of bioenergy and biomethane requires proper measurement and process control in order to achieve the best possible efficiency. In each production step, an inline analysis of the biogas is necessary.

Saving costs and gaining efficiency at the same time

The continuous measurement of methane in biogas increases efficiency. You get more CH4 from the waste and produce more electricity. The real-time methane measurement helps with the start-up and/or adjustment of the electricity generator.

Humidity measurement, in turn, ensures a longer service life and lower maintenance costs for the installation. The water vapour can condense. In particular the H2S that is still present dissolves in the water, forming a highly corrosive mixture that affects valves, pumps and the generator itself. The activated carbon filter also benefits from good humidity control. It extends the service life of the filter, thus saving costs.

A combination of CH4 and CO2 measurement in the digester tank gives you an insight into the microbial action. This allows you to intervene in time to optimise methane production. A poor CH4/CO2 balance can lead to unstable energy production.

The biogas analyser

A good biogas analyser combines the measurement of CH4, CO2 and humidity (H2O) in one instrument. It is important that the analyser can be installed directly in the process pipe or tank.

This eliminates the need for an expensive and maintenance-intensive sampling and sample preparation system. So choose a biogas analyser that combines everything in one device with almost no need for maintenance or calibration. Furthermore, it's convenient if the analyser is suitable for installation in ATEX zone 0.

More information?