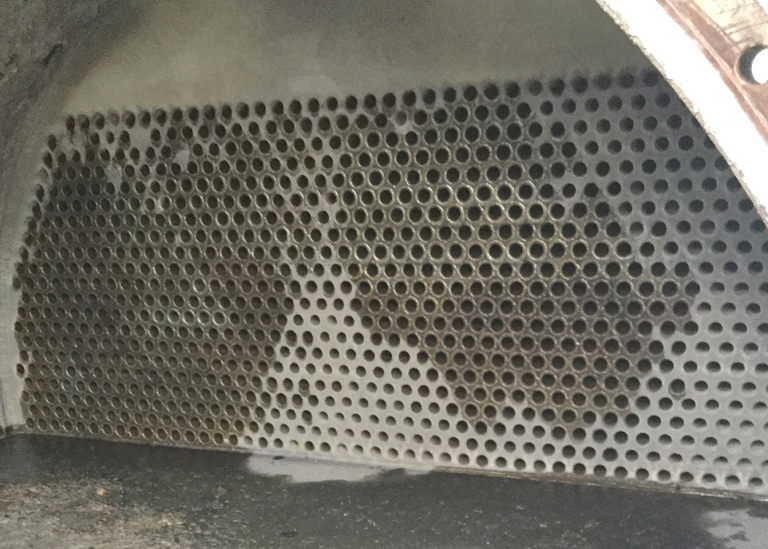

Power - Condenser

Proper functioning of the condenser is of great importance to the efficiency of the turbine. The steam condensation creates a negative pressure which results in a continuous flow of steam through the turbine. In the condenser, the steam condenses through the cooling water. The efficiency of this heat transfer must be optimal at all times. A pH and conductivity measurement are absolutely necessary for this reason. In case of a leak in the heat exchanger, cooling water enters the condensate due to the negative pressure. This is immediately noticed by these measurements.

pH measurement

The acidity of pure water is a basic parameter for its quality. Due to the extremely low conductivity, a pH measurement is not clear. It is therefore important to choose an electrode with suitable specifications for this type of water. An intelligent and therefore digital sensor helps to increase the quality and reliability.

pH calculation

The pH value of pure water in the steam cycle can be calculated under certain conditions by combining two conductivity measurements: one before and one after the ion exchanger. Combined with a classical conductivity, this gives an increased certainty and one measurement monitors the other.

ORP (redox) measurement

The measurement of the redox potential (ORP) is often mentioned in the same breath as pH measurement. A potential difference is measured against a reference electrode in both measurements and the same measuring converter is used. Today, you can measure pH, ORP and temperature with the same sensor. The ORP measurement is used to control the dosage of anti-microbial products.

Conductivity

Measuring the (specific) conductivity is the simplest and most commonly used inline measurement for checking the quality of pure water. Intelligent sensors use digital signal transmission, which makes them much more accurate than their traditional analogue predecessors.

Steam and Water Analysis System - SWAS panel

"Steam and Water Analysis System", or "SWAS" for short, is a panel that brings together the most important process analysers. The simplest form is the combination of conductivity and/or cation conductivity with dissolved oxygen and usually also pH measurement. More comprehensive systems also contain analysers for e.g. Na, Silica, TOC, etc. The panels are often fitted with a so-called "sequencer". This is a system that switches between two or more partial flows which are then analysed in turn for a certain period of time.

More information?