Gas analysis reinvented

A Probe with the Power of an Analyser

TDL (Tunable Diode Laser) analysers for measuring the concentration of one component in a gas stream have meanwhile become “mainstream”. Most devices of this type are so-called “Cross Stack” analysers. They have a light source (laser) and detector that are separately mounted directly opposite each other on both sides of the pipe or flue.

It is well known that the alignment of both parts with respect to each other is not that easy. The diameter therefore determines the optical path length (OPL) and thus the measuring range and resolution of the analyser.

In other words, the world is upside down! Normally you select a measuring device based on the desired measuring range and detection limit, not the other way around. Fortunately, things can be done differently.

Probe Analysers

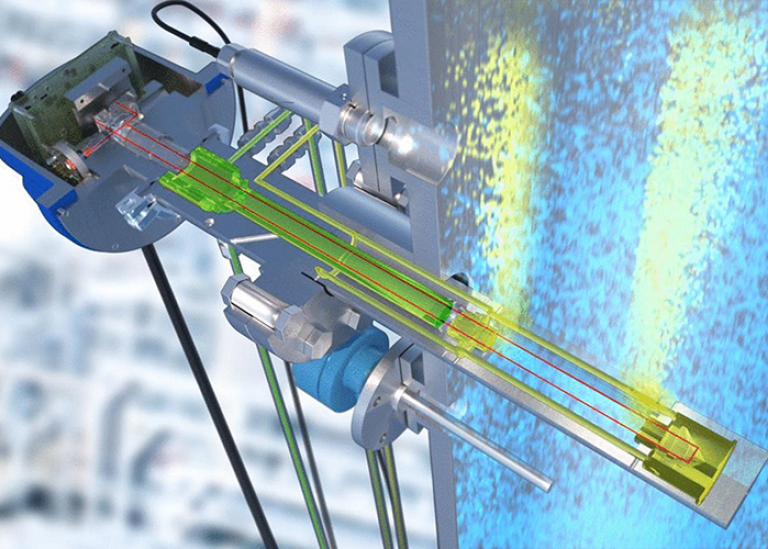

If you mount an analyser as a lance (or probe) with only one flange in your process pipe, that solves everything. Plus you get a lot of extras. You determine the length of the probe according to the measuring range, the detection limit and the resolution, as it should be. At the end of the probe is a “corner cube” that reflects the laser beam in the correct direction. The probe is aligned by the manufacturer, which eliminates one major concern. The one-flange connection also means that you only have to provide purge gas and an electrical connection on one side.

Using such a probe, you can measure inline even in relatively small process pipes, up to DN50. That is impossible with the classic “Cross Stack” analysers. You don't have to worry about periodic checks either. The optical components in contact with the gas flow are pressure resistant (up to >20bar) and the laser can be removed without any problems and without the process coming into contact with the outside air.

Small pipe, long optical path length (OPL)

Do you want to measure in low measuring ranges (ppmv level) and do you still only have a small pipe diameter? Then you run into the physical limitations of a classic system. There are accessories for probe analysers, which make the OPL two to three times greater. In a DN150 pipe you can easily achieve an optical path length of 900mm. And therefore a much lower measuring range and better resolution.

Be sure of your piece

Pre-calibrated, maintenance-free, etc. It all sounds very nice, and it is, but a person wants to be sure. That’s why periodic checking or verification is a good idea. As mentioned, you can remove the laser without interrupting the process. You can place the laser on-site onto a calibration cell without disconnecting the electrical connections. You then measure ambient air (with oxygen analysers) or you connect a calibration gas of your choice.

What about the corner cube (reflector)? That of course is in the process. No need, the degree of contamination of the optical path is continuously monitored during the measurement. The entire analyser, from laser to detector, may be checked. This is especially appreciated in inertisation processes and in installations that are difficult to access.

Conclusion

Probe analysers are a valuable alternative to standard TDLs analysers. Not only do they have a smaller “footprint”, they are more practical, you save time with installation and start-up and you can check the entire analysis system in a few minutes. All this without sacrificing the measuring range, detection limit and quality.

More information?