Calculate the efficiency of your biogas plant on the basis of the correct data

Why is the determination of the amount of moisture important and why can you make money with it?

Obviously, you want to make as much profit as possible from your (new) biogas plant as quickly as possible. Efficiency, and thus profitability, is a key factor here. Among other things, subsidies are calculated on this basis. So it is important to make that calculation based on correct data.

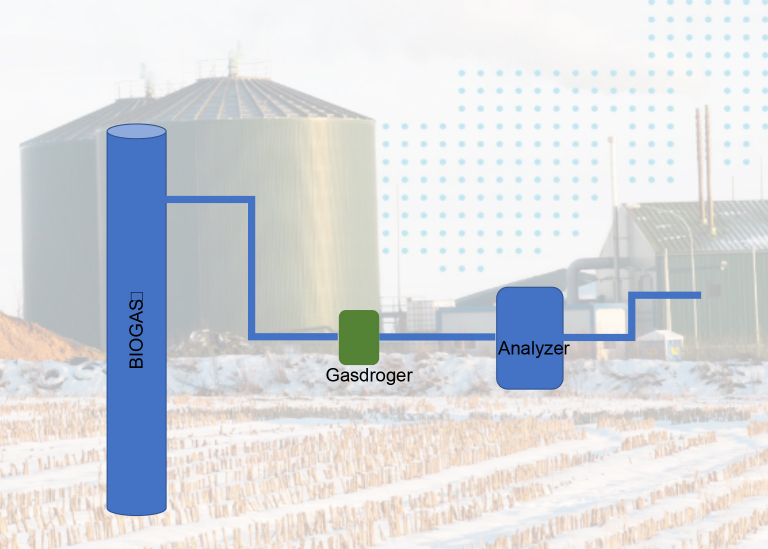

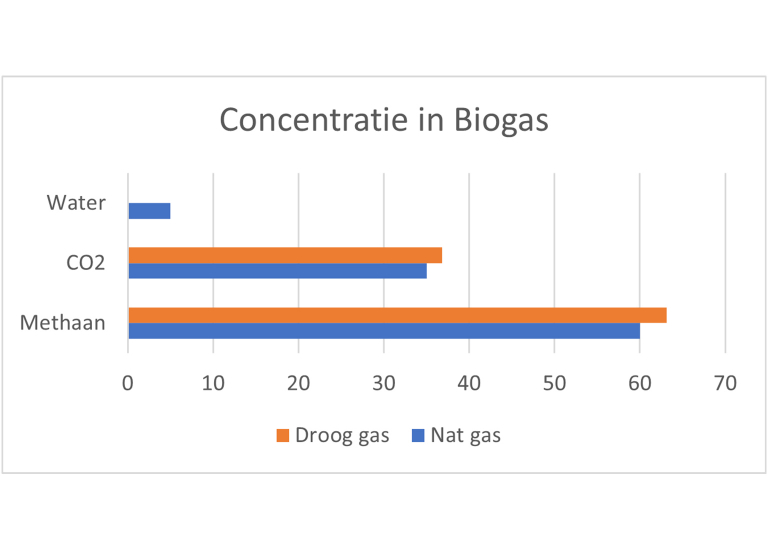

The total methane volume is calculated from the concentration (in volume percent, %vol) of methane in the biogas and the gas flow rate. The flow rate is measured directly in the process gas, which contains water (moisture). For classical extractive analysers for methane and CO2, the gas must be dry. Otherwise, they don't work. That's why the moisture is removed from the gas stream before methane and/or CO2 is measured.

By multiplying the methane concentration by the flow rate, you obtain the total methane volume. But ... you multiply a concentration in dry gas with a flow rate of wet gas. In this way, you make a significant error to your disadvantage, known as "volume error". The result is that you overestimate the energy value of your biogas. Consequently, the calculation of the return will be lower than it actually is.

Suppose you have a gas flow rate of 200 m³/h. The moist process gas contains 60%vol of methane, 35%vol of CO2 and 5%vol of water vapour. Measured using a classical analyser, you get 63.16%vol of methane and 36.84%vol of CO2.

Fortunately, the volume error can be easily avoided by measuring methane, CO2 and moisture directly in the wet process gas at the same time. An in-situ analyser is the most suitable tool for this purpose and gives you many additional advantages.

More information?