Analysis of the purest water

Water, pure water, ultrapure water, the purest water. Water, in any form, is the most commonly used chemical. In pharmaceutical production and energy production, water in its purest form is an absolute necessity! It sounds somewhat strange, but measuring and analysing ultrapure water is not as simple as you might think. ELSCOLAB has a complete range of analysers and measuring equipment especially for measuring and monitoring the quality of the purest water.

Measuring water quality in the pharmaceutical industry

Water is the most important raw material in the pharmaceutical industry. Its quality and purity is highly regulated and controlled by international bodies. Rightly so! Everyone wants a safe and pure medicine, don't they? Therefore, the monitoring of water quality is of utmost importance.

From lab tests to online analysis

At the beginning of this century, the FDA (the US Food & Drug Administration) came up with a new initiative: ‘Pharmaceutical cGMPs for the 21st century: A Risk-Based Approach’. This was the impetus for the extensive implementation of PAT (Process Analytical Technology) in pharmaceutical production, with water production at the forefront. Since then, the focus has been more on process control than product control.

Since the production of pure water (Purified Water - PW, Water For Injection - WFI, etc.) is a continuous process, it is pointless only taking a sample periodically and analysing it in the lab. Here, inline or online and real-time monitoring is necessary.

Ensure the quality of water...

The key parameters determining water quality are conductivity, TOC (Total Organic Carbon) and microbial contamination. One of the steps in the water purification process is disinfection. This is done using ozone (O3), the concentration of which also has to be determined.

Throughout the entire water purification process, from raw incoming water to the purest WFI, these parameters are determined and monitored inline or online. The slightest deviation triggers an alarm so that timely action can be taken.

... and you can sleep soundly

Measuring is one thing. Being sure of the result is another! Because you need to be sure of an inline or online analysis, we use intelligent sensors and analysers with advanced digital sensor technology. Using this tool, a permanent auto-diagnosis is carried out; an algorithm is used to make predictions and warnings are given for maintenance and calibration. The digital technology also supports electronic documentation of reports, calibrations and verifications of the sensor or analyser. That way you can always be sure that your measurement setup is in optimal condition!

Making steam to generate energy

In energy production, wherein pure water is heated to steam in order to run turbines that generate electricity, the water has to be, if possible, even purer than in the pharmaceutical industry. While energy production may be less regulated by official bodies, the producers of the plants set very high standards for water quality.

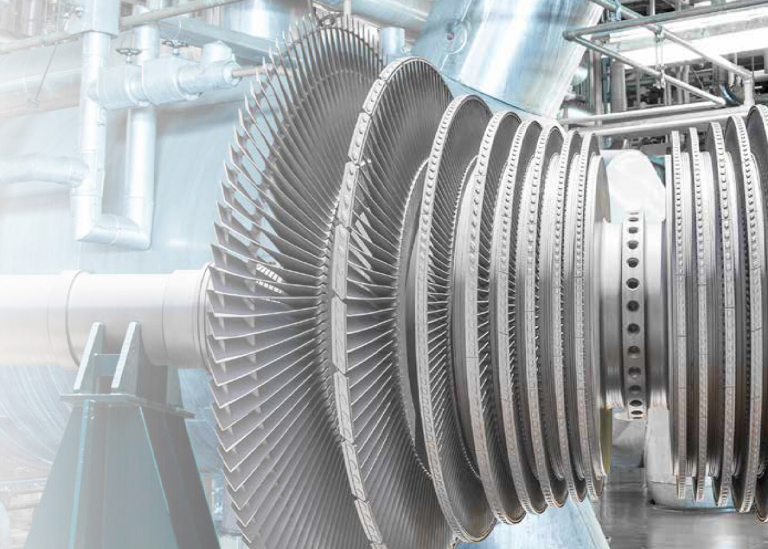

Ensure the service life of the turbine

In power plants, everything revolves around ensuring or extending the service life of the turbine! Corrosion and deposits on the turbine blades are the main dangers. That’s why water quality is permanently monitored.

From water to steam and back

A lot of water is needed for the production of electricity. Lots and lots of water. Power plants get their water from rivers and lakes and, more recently, from purified sewage. The quality of these sources is not always the same. This does not make the purification process any easier. Measuring, checking and analysing is the message!

In the steam cycle, several parameters are measured in the various steps of the process:

- pH

- Conductivity - (degassed) cation conductivity (DCC)

- TOC (total organic carbon)

- Sodium (Na)

- Silicate (SiO2)

- Chloride (Cl-)

- Sulphate (SO42_)

If you have these parameters under control, your water will meet strict standards and you will avoid premature maintenance and major costs. Today, traditional power plants are regularly switched on and off due to alternative energy sources. This has made permanent and continuous online measurement of water quality even more important.

We don't leave you out in the cold

At ELSCOLAB, support doesn’t just stop with delivery. We ensure a seamless start-up and commissioning. Our service department is available for preventive maintenance, validation and calibration of your analysers. And of course, everything is carried out according to the guidelines and with certified standards and simulators. This is the best guarantee for keeping the sensors and analysers in optimum condition for years to come, so that you can be sure of the quality of the water.

More information?