Chemistry - Phase separation - Process monitoring

A common step in the entire production process is phase separation. A distinction is made here between two or more product types. For example, liquid/solid, organic/inorganic, oil/water, solvent 1/solvent 2, liquid/gas, etc.

Process monitoring

The actual separation usually takes place in a tank. The separation is based on the difference in physical and chemical properties of the different phases. We try to measure and detect them. On the other hand, the conditions in the tank must also be monitored. There are different possibilities.

Level measurement

The product level may not exceed a minimum and/or maximum value. Various techniques can be used for this, depending on the products and the circumstances, such as: floats, capacitive sensors, pressure sensors and switches, radar measurement, etc.

Temperature measurement

Internal or external conditions can cause the temperature in the tank to rise undesirably. A temperature measurement or temperature switch can prevent many mishaps.

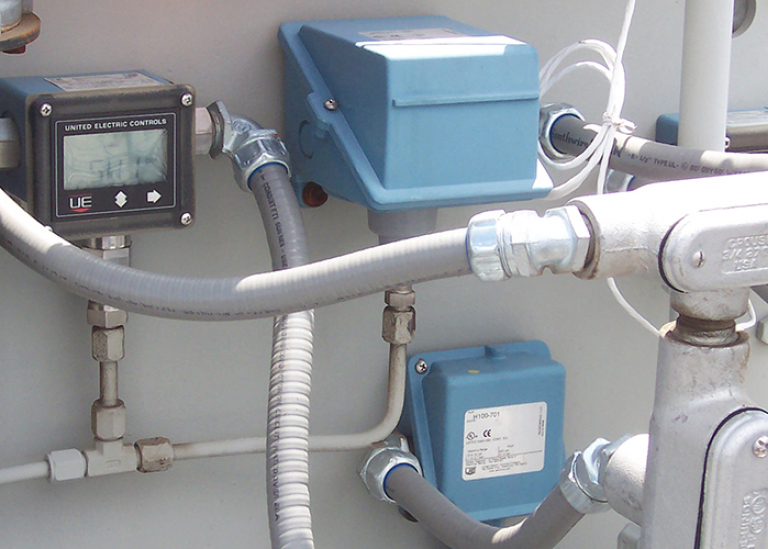

Pressure measurement

It may happen that the pressure in the headspace becomes too high, or too low. Proper monitoring of the pressure and a pressure switch will help.

More information?