Chemistry - Filtration

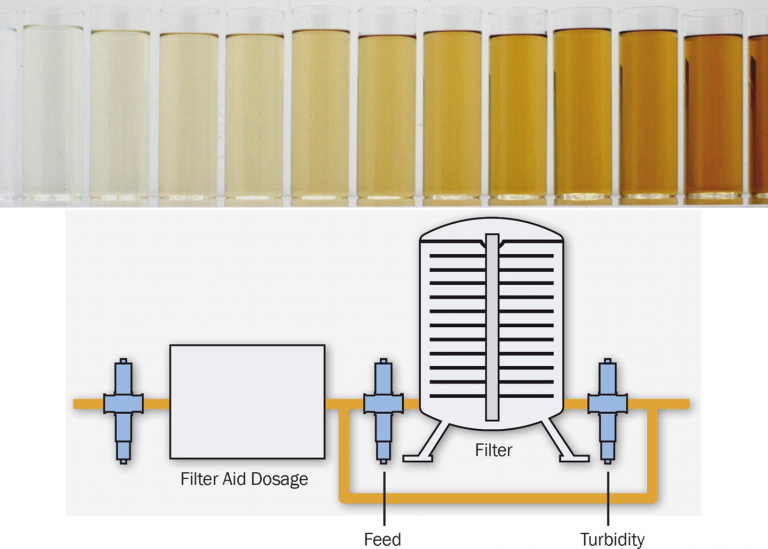

There are many different filtration techniques. They all aim to separate undissolved particles from a liquid. Very often this is water, but it can also be an organic solvent, for example. The operation, efficiency and quality of the filtration must always be monitored.

And how clear is it? A turbidity meter provides the answer.

To ensure the quality of the filtrate, it’s best to install a turbidity meter. Turbidity is measured by the light ray scattering from the particles in the liquid.

Forward scattering

Turbidity measurement for clear liquids. The measurement is done by measuring the transmission of the emitted light over a fixed path length in the pipe.

Backscattering

Turbidity measurement for liquids with medium to higher loads of undissolved substances. When taking absorbance measurements, the intensity of the light reaching the detector will decrease as the turbidity increases. Can also be used in tanks.

To filter or not to filter? The pressure will tell.

There is always a pressure difference across a filter. The pressure before the filter is always higher than after. If both pressures are equal, the filter is broken (e.g. cracked). If the pressure before the filter becomes too high, the filter is blocked (clogged).

Delta-P meter or differential pressure measurement

Measures the pressure before and after the filter and determines the differential pressure. You can see the condition of the filter at a glance.

Pressure switch

Gives a signal if the pressure is too high or too low and switches any pumps or valves on and off to protect the filter or the process and the installation.

More information?