Viscosity measurement in all applications

Save time by measuring semi-solid samples with the Heli-Plus system

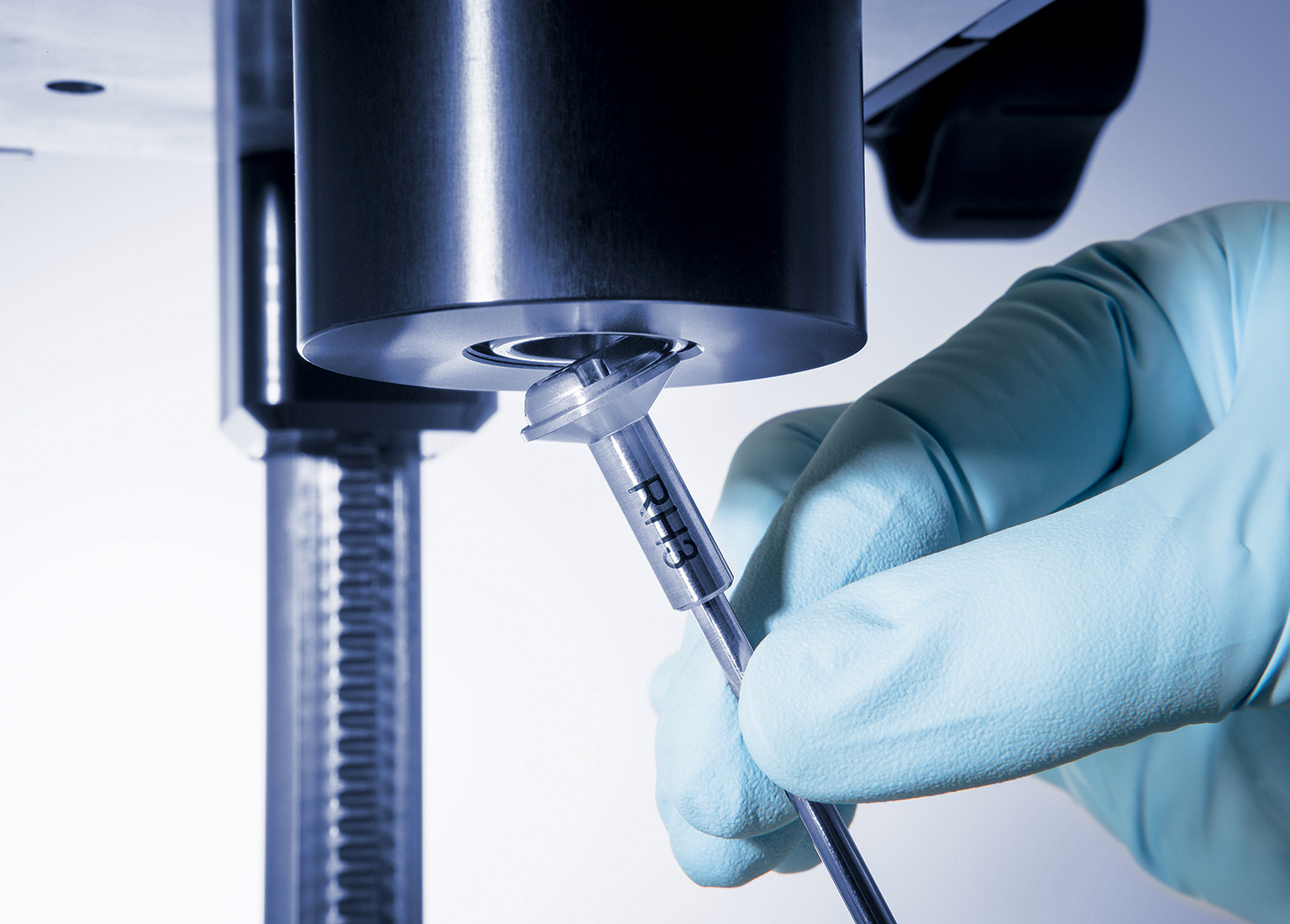

It can be challenging to measure semi-solid samples using conventional spindles, which can lose contact with the sample during a measurement. The Heli-Plus system is used for this purpose.

The motorised Heli-Plus system automatically moves the ViscoQC 100/300 head up and down in a spiral helix motion to measure the viscosity of semi-solid samples, e.g. wall fillers, gels, gelatine or sauces. This puts the spindle in continuous contact with untouched steel and allows for correct measurement.

ViscoQC's built-in digital levelling ensures that the Heli-Plus is automatically aligned. Test procedures can be fully automated by digitally defining the start and stop positions of the motorised Heli-Plus on the ViscoQC screen. Using ViscoQC and Heli-Plus therefore allows you more time to attend to other important tasks.

Convert your ordinary viscometer into a Cone & Plate viscometer in less than a minute

Convert your ViscoQC100/300 into a full-fledged Cone & Plate viscometer in less than a minute with the brand new PTD100. You thereby have a conventional viscometer and a Cone & Plate viscometer in the same device.

Made for small volumes, from 0.5 ml to 2 ml, ideal when large amounts of sample are too expensive or difficult to obtain. Perfect gap setting at every measurement (through automatic gap setting), spindle recognition with magnetic coupling and digital levelling providing full traceability and reproducibility at every measurement.

A built-in Peltier heating element allows you to completely digitally select the temperature between 0°C - 100°C, with T-ready™ technology that waits until the steel is at the exact right temperature.

Guarantee of good viscosity measurement

With years of experience in viscosity, we will ensure together that a correct setup is proposed, adapted to your specific application. We always remain at your disposal after purchase if you have any questions or require support. We also ensure that commissioning and personal practical training is given by one of our experts with each device. Our annual quality device service ensures that your device always takes correct measurements and is calibrated before use.

Moreover, an independent seminar on viscosity is also held every year, which provides insight into viscosity and rheology measurement and enables you to make optimal choices in method design, for example. On-site training can also be provided on request.

Why choose a ViscoQC?

- Magnetic spindle connection for faster testing + unique automatic Toolmaster™ spindle recognition for traceability of each test, which reduces user errors and improves the quality system.

- TruMode™ which ensures with new product developments that you can find the ideal spindle/speed configuration without losing significant time.

- Optional V-curve software for programmability/analysis (to apply statistics, yield point calculations, etc.).

- Automatic data collection possible with V-collect or can be integrated into your LIMS system with the ViscoQC 300.

- Instrument qualification packages that ensure your device can be made pharma-compliant in 1 day.

- Options for DIN/SSA/UL adapters for a multifunctional system that can be adapted to all needs.

- Peltier heating elements that can heat and cool very accurately to within ±0.1°C to take fast and accurate measurements without a hot water bath.

- Price/quality ratio at the top of its segment.

More information?

Discover the ViscoQC100 and ViscoQC300 devices or contact us for your vicosity measurement.